Smt Equipments Application

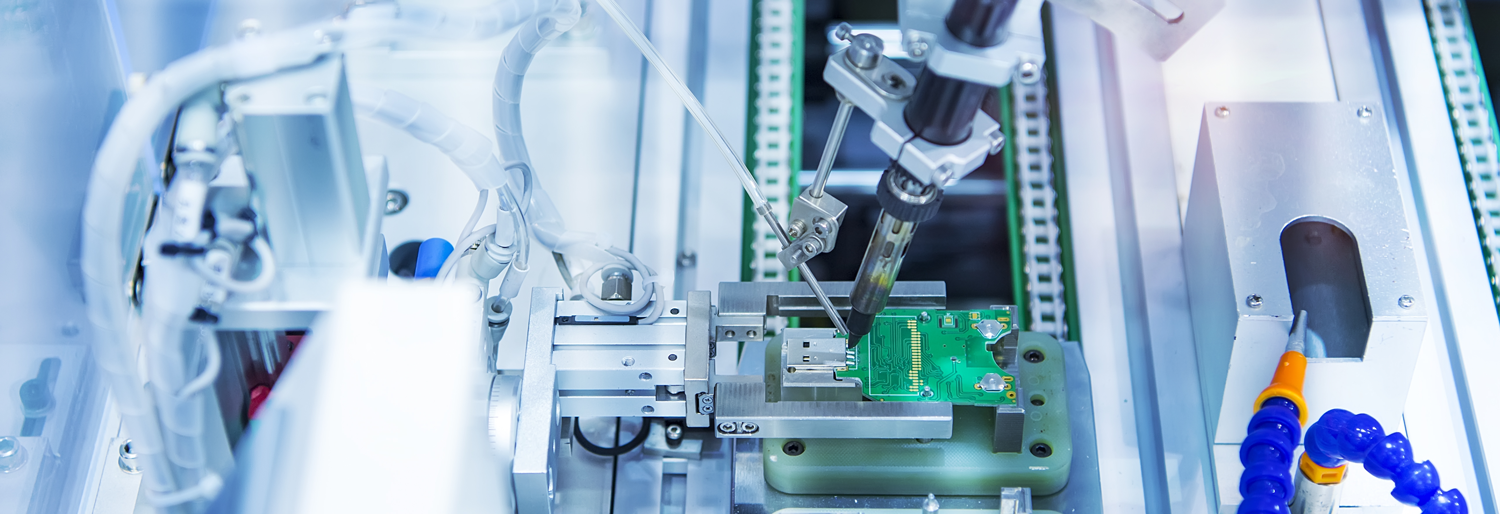

Unlocking Precision and Efficiency with HCT SMT Equipment: Assembling Tomorrow's Technology Today!

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Smt Equipments Application

Unlocking Precision and Efficiency with HCT SMT Equipment: Assembling Tomorrow's Technology Today!

Consumer electronics have become an integral part of modern life, enriching our daily experiences and connecting us to the world. The Surface Mount Technology (SMT) Pick and Place Machine plays a pivotal role in the manufacturing of consumer electronic devices, revolutionizing the assembly process and enabling the production of compact, efficient, and feature-rich products. we will explore the various applications of SMT Pick and Place Machines in the consumer electronics industry

SMT (Surface Mount Technology) Pick and Place Machines play a crucial role in the manufacturing of various LED (Light Emitting Diode) products.The Surface Mount Technology (SMT) process for LED (Light Emitting Diode) pick and place offers several advantages over traditional through-hole technology when it comes to assembling LED-based electronic devices. These machines automate the process of placing surface mount LED components onto PCBs (Printed Circuit Boards), ensuring accurate and efficient assembly.

SMT placement machines have significant applications in the aerospace and defense industries, where precision, reliability, and high-performance electronics are critical. These machines play a crucial role in the manufacturing of electronic components and systems used in various aerospace and defense applications.