Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

SMT Machine

SMT Machine

(15)SMT machines, or Surface Mount Technology Machines, are essential equipment used in the electronics manufacturing industry to mount electronic components onto printed circuit boards. They automate the process of component placement, providing high accuracy and precision while reducing the cost and time needed to produce electronic products.

SMT machines consist of:

SMT machines typically consist of a pick-and-place machine, a reflow oven, and an inspection machine. The pick-and-place machine picks up electronic components from their feeders and places them on the circuit board. The reflow oven then melts the solder on the board to connect the components, and the inspection machine verifies the quality of the connection.

Advantages of SMT (Surface Mount Technology) machines:

‧ High accuracy and precision in component placement.

‧ Consistency in assembly.

‧ Greater flexibility in handling a wide range of component sizes and shapes.

‧ Improved production efficiency and speed.

‧ Reduction of manual labor, reducing the chance of human error.

‧ Lower assembly costs compared to through-hole technology.

‧ Smaller size and weight of components, making products more compact and lightweight.

‧ Better electrical performance due to shorter interconnections and smaller parasitic effects.

‧ Faster turnaround time for production and prototyping.

‧ The ability to handle higher circuit densities and more complex designs.

Applications of SMT (Surface Mount Technology) machines:

Consumer Electronics: SMT machines are widely used in the production of consumer electronics such as smartphones, tablets, laptops, and televisions.

Automotive: SMT machines are used in the manufacturing of automotive components such as sensors, switches, and controllers.

Aerospace: SMT machines are used in the production of various components for aerospace applications such as control systems, communication systems, and navigation systems.

Medical Devices: SMT machines are used in the production of medical devices such as pacemakers, monitors, and diagnostic equipment.

Defense: SMT machines are used in the manufacturing of defense equipment such as missile systems, radar systems, and communication systems.

Industrial Equipment: SMT machines are used in the production of industrial equipment such as control systems, sensors, and monitoring devices.

LED Lighting: SMT machines are used in the production of LED lighting products such as LED strips, bulbs, and fixtures.

Overall, the widespread use of SMT machines in various industries highlights their importance in the production of high-quality electronic products. SMT machines continue to play an essential role in the electronics manufacturing industry, facilitating the production of high-quality electronic products. As technology continues to evolve, SMT machines are becoming more advanced, offering improved features and capabilities, such as the ability to handle smaller components and more complex designs.

In conclusion, SMT machines are crucial equipment in the electronics manufacturing industry, providing high accuracy and efficiency while reducing costs and time. Despite some limitations, their ongoing evolution and technological advancements offer the potential for further improvements in the production of electronic products in the future.

HCT is a trustworthy SMT Machine Supplier & Factory in China. Serving Worldwide | Lifetime Service Support | 1-Year Free Guarantee. We carry both Automated SMT Pick-and-place Machines and Semi-automated SMT Pick-and-place Machines so you can rest assured we’ll have the equipment you need, no matter your application or industry. If you pursue Hi-quality, Hi-stable, Competitive price SMT machines, HCT is your best choice! If you are interested in any of our products or have an OEM order to fulfill, please feel free to contact us now. Working with us will save you money and time.

HCT-810L Automatic 10 Heads DOB Pick and Place Machine

The HCT-810L is a cutting-edge placement machine equipped with the advanced Flying Vision Alignment System. With its bottom fixed cameras and 10 spindles on a single gantry, this machine offers exceptional precision and speed in component placement.

HCT-550LV Automatic 10 Heads LED Chip Mounter

The machine is built with high-quality hardware components from renowned brands, ensuring long-term reliability and durability. This results in reduced maintenance requirements and increased machine uptime, contributing to overall operational stability and customer satisfaction.

HCT-550LW Automatic 10 Heads LED Placement Machine

Experience the power of advanced LED placement technology with our HCT-550LW automatic 10 heads LED placement machine.This cutting-edge machine is designed to provide high-precision and high-speed placement of LED components, making it an essential tool for LED manufacturing processes.

HCT-610LV Automatic 10 Heads DOB Pick and Place Machine

Highest LED DOB high component applicability of high-speed chip mounters. All LED lighting products, including flexible PCB strips, circular LED light bulb boards, and even boards with asymmetrical shapes, are suitable for this technology. LED PCBs up to 600mm long can be assembled in a single pass.

HCT-530LV Automatic 1.2M LED Pick and Place Machine

The desktop automatic pick and place machine HCT-530LV Automatic 1.2M LED Pick and Place Machine was created with research laboratories and small to medium manufacturing firms in mind, but it may also be used by serious hobbyists. These robotic pick-and-place systems are appropriate for small-batch manufacturing, in-lab product testing, research and development, LED SMT assembly, and other related procedures.

HCT-600SV Automatic 8 Heads LED Placement Machine

Our newest SMD LED pick and place machine can precisely match the precision requirements of LED products when compared to other machines made on the conventional SMT assembly line. The installation speed must be quick when using the automatic LED bulb-making machine, and at the same time, the length of the printed circuit board on the placement machine must be at least 1200 mm. More importantly, the criteria for speed and size are also high.

HCT-1200-SV Automatic 8 Heads LED SMD Pick & Place Machine

The PCB pick and place machine is a type of SMT machinery used in the SMT manufacturing line to achieve high-speed and high-precision component placement. The PCB SMT pick and place equipment is typically set up following the dispenser screen printing equipment. By adjusting the mounting head, the surface mount components are attached precisely. The most crucial, intricate, and significant piece of machinery in the entire SMT line is the PCB pad.

HCT-V8 Automatic Placement Machine for LED Lens Assembly

Surface-mounted components are placed precisely on the PCB using the SMT PCB machine by moving the mount head. based on the components of the PCB SMT machine and the workflow's design concept. PCB mounting devices have been introduced with a variety of features, applications, and quality levels.

HCT-830L High-speed LED Chip Mounter

With the development of science and technology, electronic items are a part of everyone's life. To fulfill its purpose, every electrical product needs a PCB as a carrier. Some PCBs contain hundreds of components, and manual soldering of PCBs has long fallen short of market demands. The PCB component placement machine is the most crucial piece of the PCB assembly chain, and the simplest SMT line typically comprises a solder printer, a pick and place device, and a reflow oven.

HCT-330LV Automatic 6 Heads LED SMT Machine

A precise industrial PCB pick-and-place robot, the SMT pick-and-place machine combines machine-electric-optical, computer control, and automation technology. Through features like suction-displacement-positioning-placement, it quickly and correctly positions SMC/SMD components on the designated pad position on the PCB board without causing any harm to the parts or printed circuit boards.

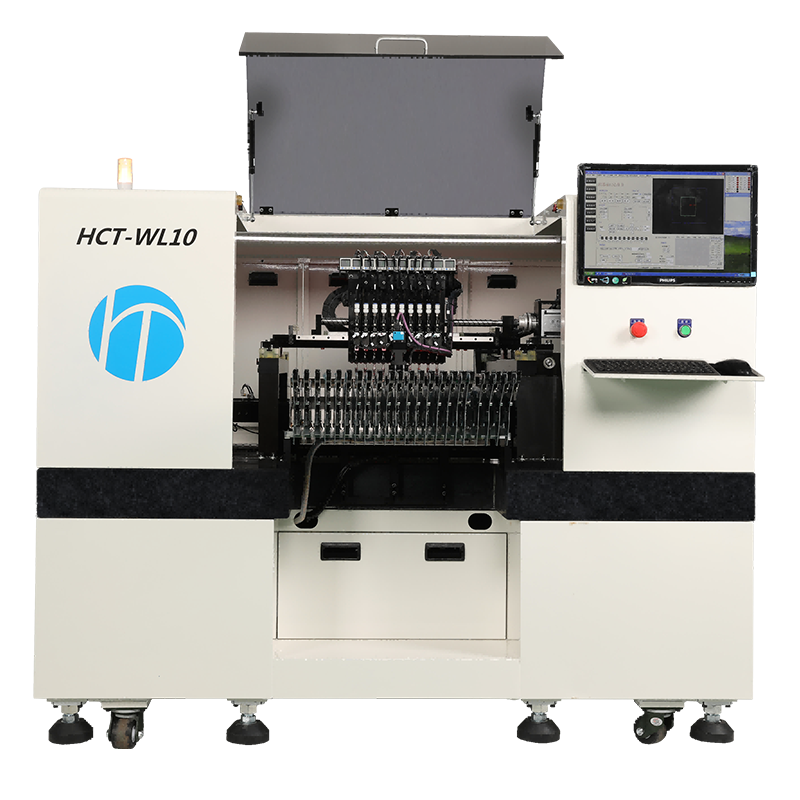

HCT-WL10 Automatic Copper Wire Lamp Placement Machine

Different working files are loaded onto the SMT pick and place machine in order to attach the corresponding PCB. Please get in touch with us if you have any questions concerning the cost of a PCB pick and place machine, PCB soldering machine, PCB component placement machine, or PCB SMT assembly machine.

HCT-530SV Semi-auto 8 Heads LED SMD Mounter

The pick and place machine is the most precise and complicated piece of SMT equipment since it is the most crucial part of the SMT manufacturing line. The working environment must meet a number of conditions for the pick and place machine. The slider's service life can be increased and its failure rate can be decreased in a positive work environment.