Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Advancing Electronics Manufacturing with Precision: Exploring Pick and Place Machines for PCB Assembly

In the intricate realm of electronics manufacturing, where precision and speed are paramount, pick and place machines for PCB assembly emerge as the unsung heroes. These robotic marvels have revolutionized the assembly process, catapulting efficiency to new heights. Join us on a journey through the intricacies of pick and place technology and discover how these machines are reshaping the manufacturing landscape.

Unveiling Pick and Place Machines:

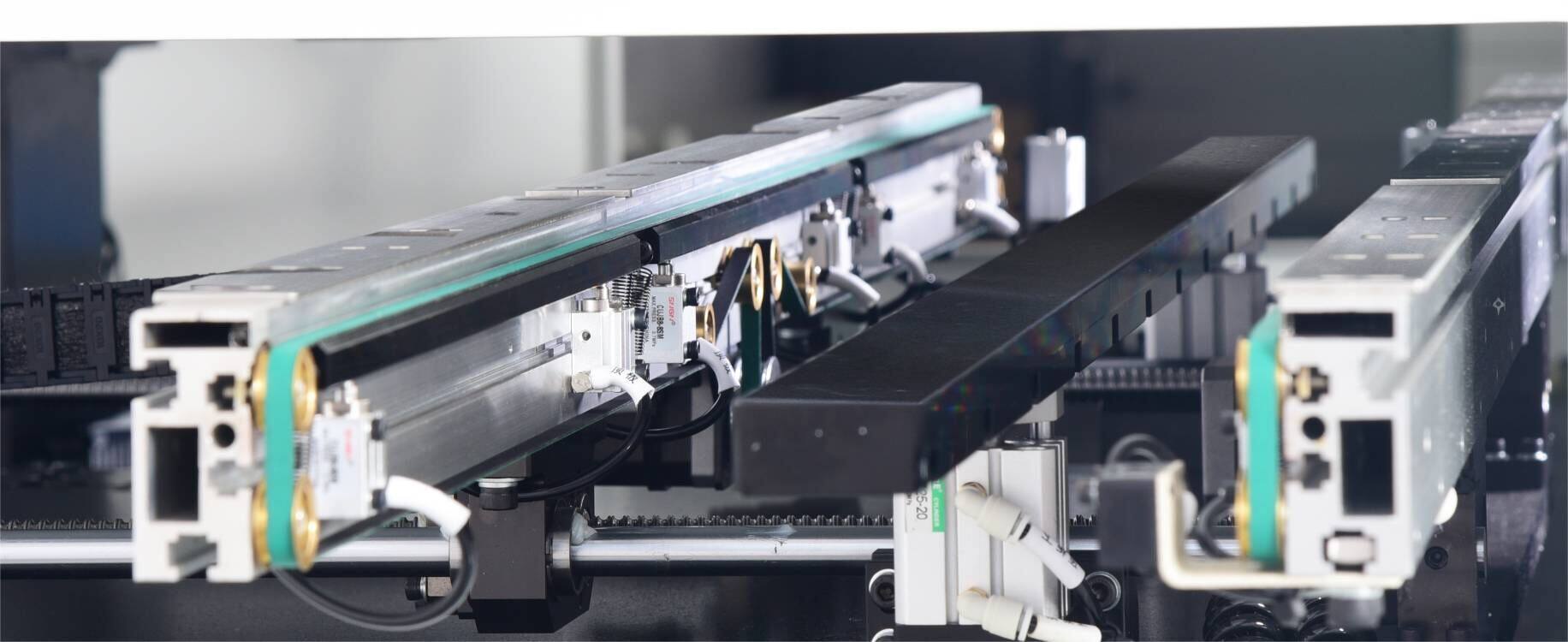

At the heart of PCB assembly lies the pick and place machine—a sophisticated robotic device designed to precisely position surface-mount components onto circuit boards. Gone are the days of manual component placement; these machines automate the process with unparalleled accuracy and efficiency. Let's delve deeper into their workings and significance.

Precision Perfected: The Evolution of Pick and Place Technology:

The evolution of pick and place machines for PCB assembly traces a trajectory of relentless innovation, marked by significant milestones in precision engineering. From rudimentary manual systems to the cutting-edge robotic solutions of today, let's trace the evolution of this indispensable technology:

1. Manual Assembly Era: In the nascent stages of electronics manufacturing, component placement was a labor-intensive affair reliant on skilled technicians. Each component was meticulously placed by hand, a painstaking process susceptible to human error and inefficiency.

2. Semi-Automated Systems: As demand surged and technology advanced, semi-automated pick and place systems emerged as a bridge between manual labor and full automation. These systems incorporated basic mechanical or pneumatic mechanisms to aid technicians in component placement, albeit with limited speed and precision.

3. Rise of Fully Automated Solutions: The advent of fully automated pick and place machines for PCB assembly heralded a paradigm shift in PCB assembly. Equipped with state-of-the-art robotic arms, advanced vision systems, and intelligent software algorithms, these machines revolutionized the production process. Today's pick and place machines boast unprecedented speed, precision, and versatility, capable of handling a diverse range of components with unmatched efficiency.

Key Features Redefining Efficiency:

What sets modern pick and place machines for PCB assembly apart are their advanced features and capabilities, engineered to optimize efficiency and productivity. Let's explore some of the key attributes driving their success:

1. High-Speed Placement: Pick and place machines are synonymous with speed, capable of placing thousands of components per hour with unrivaled precision. This accelerated throughput not only accelerates production cycles but also enhances time-to-market for electronic devices, a crucial advantage in today's fast-paced industry.

2. Sublime Precision: Precision is the hallmark of pick and place technology, underpinned by advanced vision systems and robotic precision. These machines can accurately position components with micron-level accuracy, ensuring optimal solder joint integrity and electrical performance.

3. Component Compatibility: Versatility is another hallmark of pick and place machines, capable of handling a myriad of component types, sizes, and shapes. From minuscule resistors and capacitors to complex ICs and connectors, these machines seamlessly adapt to diverse component requirements, making them indispensable across a spectrum of applications.

4. Flexibility in Programming: Intuitive software interfaces empower operators to effortlessly program pick and place machines, facilitating rapid reconfiguration for different PCB layouts and production runs. This flexibility enables manufacturers to swiftly adapt to changing production requirements, optimizing resource allocation and minimizing downtime.

Applications Across Industries:

Pick and place machines for PCB assembly find ubiquitous use across various industries, powering the assembly of electronic devices in diverse applications:

1. Consumer Electronics: From smartphones and tablets to wearables and IoT devices, pick and place machines drive the high-volume production of consumer electronics, ensuring rapid assembly with uncompromising quality.

2. Automotive Electronics: In the automotive industry, pick and place machines play a critical role in assembling electronic components for vehicle subsystems, including infotainment systems, engine control units (ECUs), and advanced driver assistance systems (ADAS).

3. Industrial Automation: Industrial automation relies on pick and place machines for the assembly of control panels, PLCs, and instrumentation electronics. These machines ensure the reliability and performance of critical automation systems in diverse industrial settings.

4. Medical Devices: The medical device industry benefits from the precision and reliability of pick and place machines in the assembly of diagnostic equipment, patient monitoring devices, and implantable medical devices. These machines uphold the stringent quality and regulatory standards of the healthcare sector.

Pioneering the Future: Emerging Trends and Innovations:

As technology continues to evolve, pick and place machines for PCB assembly are poised to embrace new frontiers of innovation. Some emerging trends to watch include:

1. AI and Machine Learning Integration: Incorporating artificial intelligence (AI) and machine learning algorithms into pick and place machines can enhance predictive maintenance, optimize production scheduling, and improve component recognition accuracy.

2. Collaborative Robotics: Collaborative robots (cobots) equipped with pick and place capabilities offer the potential for safe and efficient human-robot collaboration on the factory floor. These cobots can work alongside human operators, enhancing productivity and flexibility in manufacturing operations.

3. Additive Manufacturing Synergy: The integration of pick and place technology with additive manufacturing processes, such as 3D printing and printed electronics, could unlock new possibilities for on-demand fabrication and customization of electronic devices.

Conclusion: Paving the Path to Precision and Efficiency

In conclusion, pick and place machines for PCB assembly represent a pinnacle of precision engineering, driving efficiency and productivity in electronics manufacturing. With their advanced features, versatility, and wide-ranging applications, these machines are indispensable assets across industries. As we venture into the future, the continued evolution of pick and place technology promises to unlock new realms of efficiency, innovation, and competitiveness in the electronics manufacturing landscape.