Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

HCT-1200-SV Automatic 8 Heads LED SMD Pick & Place Machine

The PCB pick and place machine is a type of SMT machinery used in the SMT manufacturing line to achieve high-speed and high-precision component placement. The PCB SMT pick and place equipment is typically set up following the dispenser screen printing equipment. By adjusting the mounting head, the surface mount components are attached precisely. The most crucial, intricate, and significant piece of machinery in the entire SMT line is the PCB pad.

Technical Parameters - Automatic 8 Heads LED SMD Pick & Place Machine

|

Model |

HCT-1200-SV |

|

|

Alignment |

Flying Vision Alignment System |

|

|

Number of Spindles |

8 Spindles x 1 Gantry |

|

|

RatedPlacement Speed |

Vision Alignment |

LED 283540,000 CPH (Optimum) |

|

Placement Accuracy |

±0.05mm (Based on the standard chips) |

|

|

Mechanical Precision |

±0.02mm |

|

|

Component Range |

Vision Alignment |

0603(inch)~5050~7474(mm), high-power LED,IC<10mm |

|

Max Height |

H=10mm (can handle max. 18mm without vision alignment) |

|

|

Board Dimension(mm) |

Minimum |

50(L) x 50(W) |

|

Maximum |

1,200(L) x 380(W) |

|

|

PCB Thickness |

0.5 - 3.0 |

|

|

Board Handling Method |

Inline Conveyor |

|

|

Tape Feeder |

Feeder Type |

ElectricFeeder |

|

Feeder Capacity |

20 (12mm) |

|

|

Optional |

8mm, 12mm, 16mm, 24mm |

|

|

Utility |

Power |

AC 220V/240V 50/60Hz, Single phase |

|

Max3.2KW |

||

|

Air Consumption |

0.55-0.7MPa (5.6-7.1kgf/cm2) Built-in Vacuum Pump for Nozzles |

|

|

Mass |

Approx.1680kg |

|

|

External Dimension(mm) |

2,000(L) x1,150(D) x 1,500(H) |

|

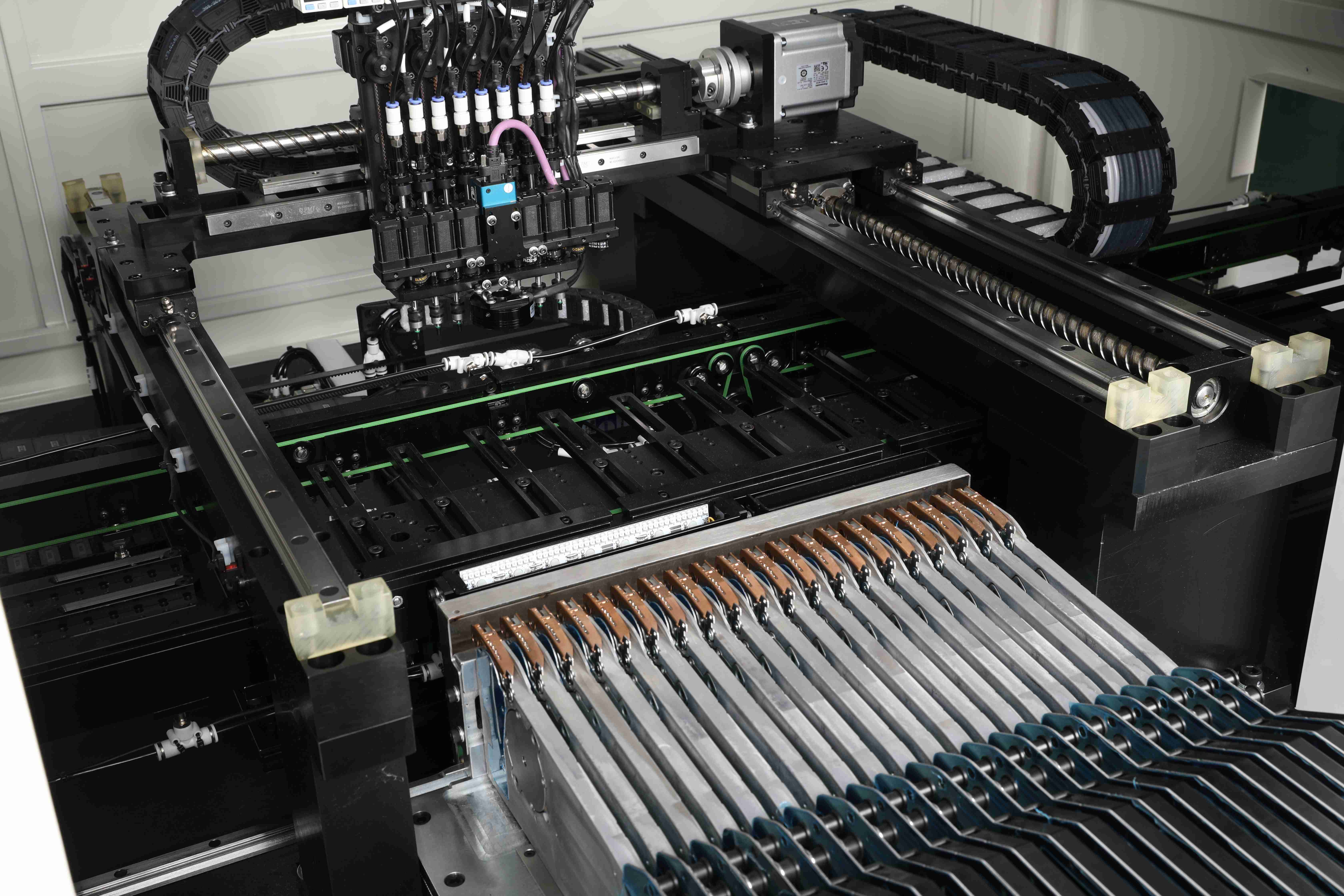

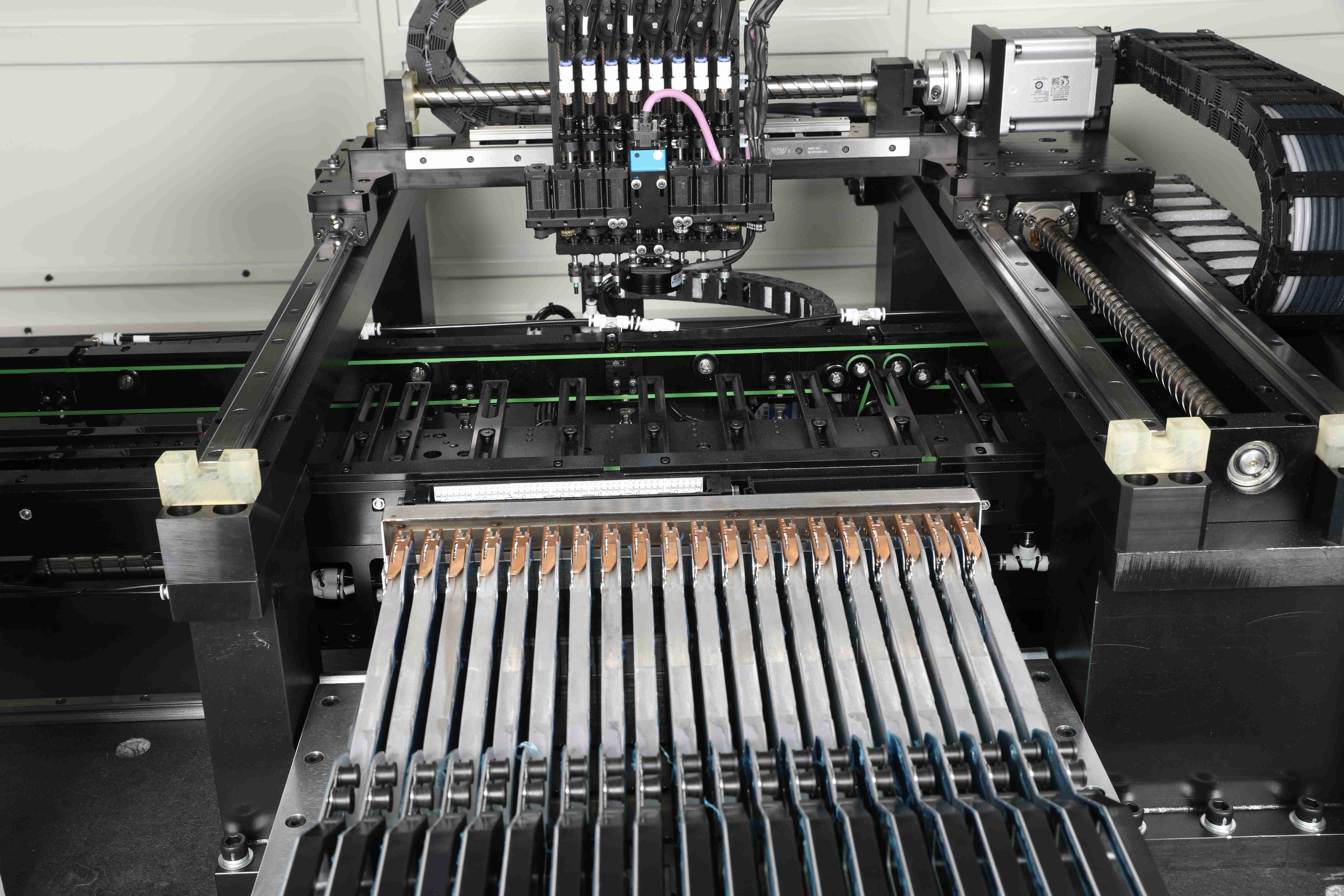

Product Features - Automatic 8 Heads LED SMD Pick & Place Machine

1. High accuracy: Each of the eight pick-up heads is equipped with a FLYING vision alignment camera to guarantee high accuracy.

2. High-speed: Maximum placement speed reaching 0.09s/chip.

With a SMEMA-compatible inline conveyor for line automation.

Each mounting head has its Z - direction closed-loop stepper motor, which is designed for vertical motion

3. Places SMD components from 0603 to 7474, including resistors, capacitors, high-power LEDs, and standard and irregularly shaped LEDs.

4. Suitable for all LED lighting products, including T5/T8, flexible PCB strips, circular LED light bulb boards, and even irregularly shaped boards. Assembles LED PCBs up to 1.2 meters long in a single pass.

5. Excellent quality hardware support by using international famous brands ensures placement repeatability and precision.

6. Self-developed software simplifies production, easy to operate, and programming.

The PCB pick and place machine is a kind of SMT equipment used to achieve high-speed and high-precision placement of components in the SMT production line. The PCB SMT pick and place machines are normally configured after the dispenser screen printing machine. The surface mount components are accurately mounted by moving the mounting head. The PCB pad is the most critical, complex, and important equipment in the entire SMT line. The use of the CNC pick and place machine for PCB assembly line requires a certain amount of professional basic knowledge in this field including but not limited to various resistance-capacitance chip components, IC, PCB design and processing, steel mesh, solder paste brushing, reflow soldering, connection table, and inspection, etc related information.

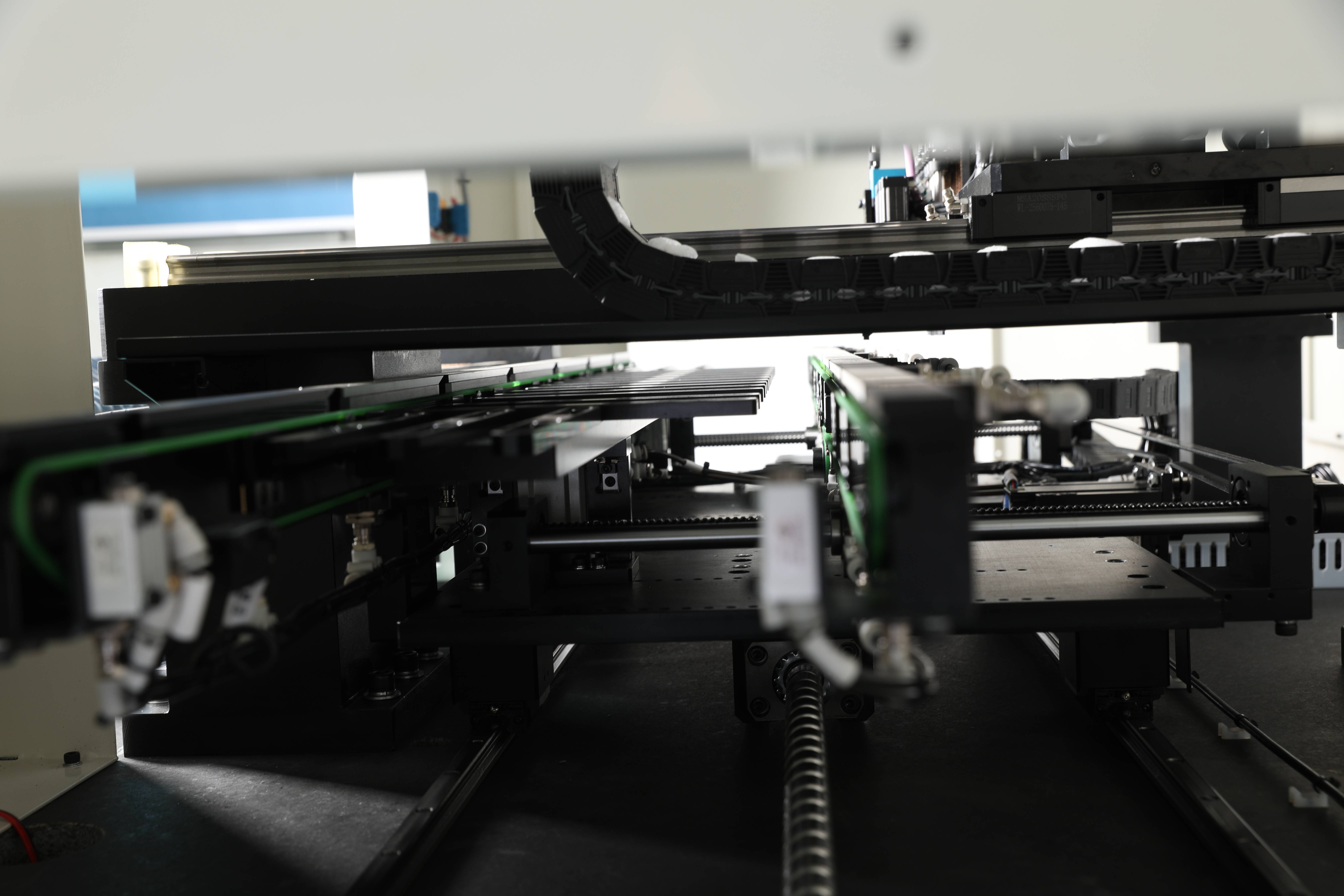

Product Display - Automatic 8 Heads LED SMD Pick & Place Machine