Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

China Small Reflow Soldering Machine

A small reflow soldering machine is a compact and versatile piece of equipment used for soldering electronic components onto printed circuit boards (PCBs) in surface mount technology (SMT) assembly processes. These machines are designed to offer efficient and precise soldering capabilities suitable for small-scale production, prototyping, research laboratories, and educational purposes.

Key Features:

-

Compact Size: Small reflow soldering machines are typically designed to occupy minimal space, making them suitable for use in small workshops, laboratories, or even on desktops.

-

Ease of Use: User-friendly interfaces and intuitive controls make small reflow soldering machines accessible to operators with varying levels of expertise.

-

Precise Temperature Control: Despite their compact size, these machines offer precise temperature control to achieve optimal soldering profiles for different types of solder paste and PCB designs.

-

Heating Zones: Although smaller in size, these machines may still feature multiple heating zones to accommodate temperature profiling and ensure uniform heating across the PCB surface.

-

Conveyor System: Some small reflow soldering machines may incorporate a conveyor system to transport PCBs through the soldering process, enabling consistent and reliable soldering results.

-

Profile Management: Advanced models may offer profile management capabilities, allowing users to store and recall temperature profiles tailored to specific soldering requirements.

-

Visual Monitoring: Transparent viewing windows or built-in cameras may be provided to allow operators to monitor the soldering process in real-time.

-

Nitrogen Compatibility: Some models may support the option for nitrogen atmosphere control to minimize oxidation and improve solder joint quality, particularly for lead-free soldering.

Benefits:

-

Space-Saving: The compact size of small reflow soldering machines makes them ideal for environments where space is limited, such as small workshops, laboratories, or educational institutions.

-

Cost-Effective: Small reflow soldering machines typically offer cost-effective soldering solutions compared to larger industrial-scale machines, making them suitable for budget-conscious users.

-

Versatility: Despite their small size, these machines can accommodate a wide range of PCB sizes and soldering requirements, offering versatility for various applications.

-

Ease of Integration: Small reflow soldering machines are easy to integrate into existing production lines or workstations, allowing users to upgrade their soldering capabilities without significant infrastructure changes.

-

Quick Setup: These machines often feature quick setup times, allowing users to start soldering operations with minimal preparation or training.

Considerations:

-

Throughput: Evaluate the machine's throughput capabilities to ensure it can meet production volume requirements efficiently.

-

Temperature Uniformity: Verify that the machine provides uniform heating across the PCB surface and between different heating zones to prevent uneven soldering.

-

Compatibility: Ensure the machine is compatible with the specific solder paste alloys and PCB designs used in your assembly process.

-

Maintenance and Support: Choose a small reflow soldering machine from a reputable manufacturer with reliable maintenance and support services to minimize downtime and ensure long-term operation.

Here's an overview of the features and operation of a small reflow soldering machine:

-

Compact Size:

- Small reflow soldering machines are designed to be space-saving, making them ideal for environments where space is limited. They are often benchtop-sized or desktop-sized, allowing for easy integration into workstations or production lines.

-

Precise Temperature Control:

- Despite their smaller size, these machines offer precise temperature control to ensure consistent soldering results. They typically feature PID (Proportional-Integral-Derivative) temperature control algorithms and thermocouple sensors to monitor and regulate temperature profiles accurately.

-

Multiple Heating Zones:

- Many small reflow soldering machines have multiple heating zones (usually two to four) to accommodate different solder paste types and achieve optimal soldering results. Each heating zone can be independently controlled to create custom temperature profiles tailored to specific soldering requirements.

-

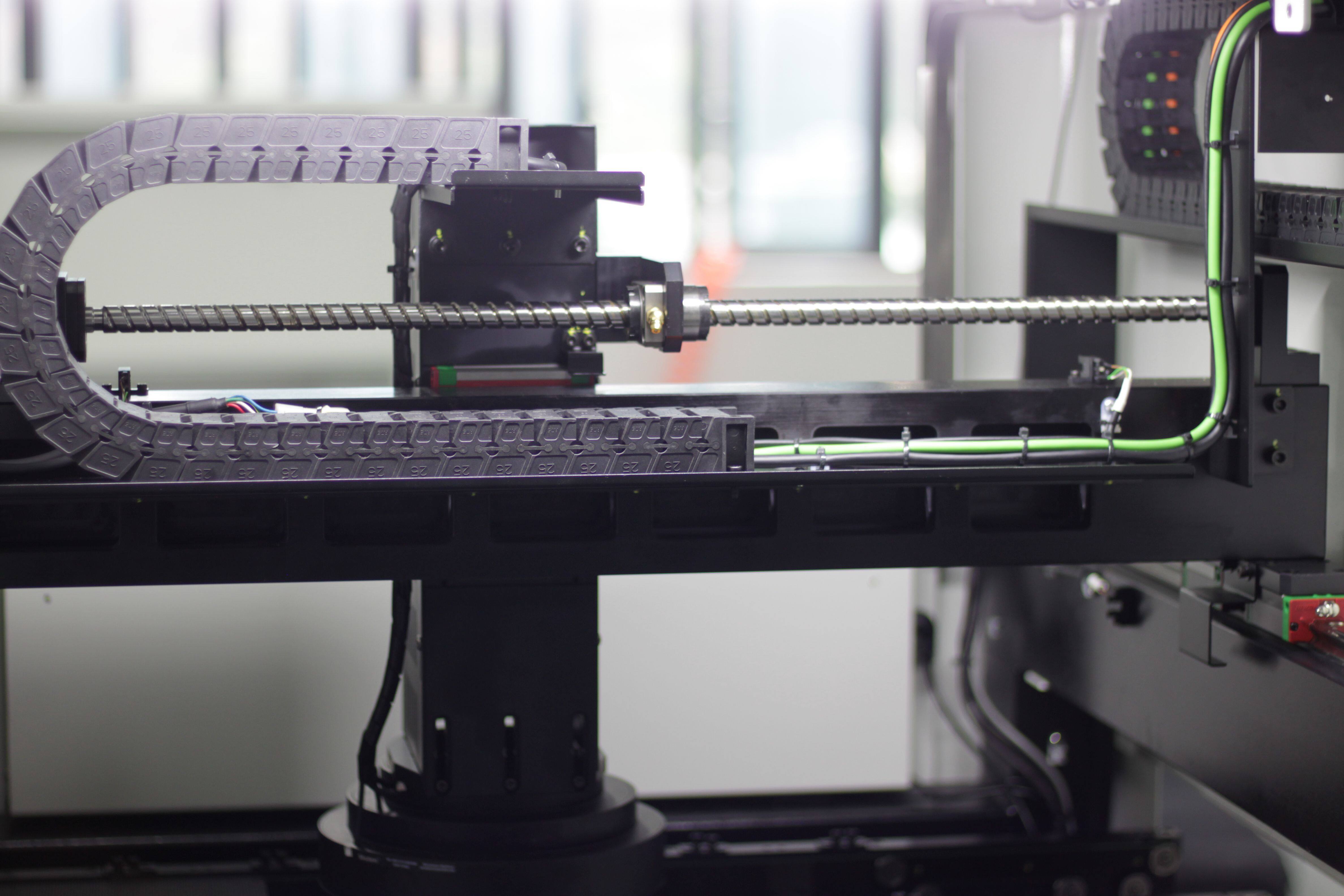

Conveyor System:

- Small reflow soldering machines may include a conveyor system to transport PCBs through the heating zones during the soldering process. The conveyor speed can be adjusted to control the dwell time of PCBs in each heating zone, optimizing the reflow soldering process.

-

User-Friendly Interface:

- These machines often feature intuitive user interfaces with touchscreen displays or simple button controls for easy operation. Users can program temperature profiles, monitor process parameters, and adjust settings with minimal training or technical expertise.

-

Built-in Safety Features:

- Safety features such as overheat protection, emergency stop buttons, and automatic shutdown mechanisms are commonly integrated into small reflow soldering machines to prevent accidents and ensure operator safety.

-

Versatility:

- Small reflow soldering machines are versatile and can handle a wide range of PCB sizes and shapes. They are suitable for soldering various types of surface mount components, including resistors, capacitors, integrated circuits, and connectors.

-

Cost-Effective Solution:

- Small reflow soldering machines offer a cost-effective solution for small-scale production or prototyping projects compared to larger, automated reflow ovens. They provide the necessary soldering capabilities while minimizing upfront investment and operating costs.

Describe The Situation Of Small Reflow Soldering Machine In China

In China, the market for small reflow soldering machines is witnessing steady growth, driven by the increasing demand for electronics manufacturing equipment in various industries such as consumer electronics, automotive, telecommunications, and industrial automation. The rapid expansion of the electronics manufacturing sector, coupled with advancements in technology and automation, has fueled the adoption of reflow soldering machines among small and medium-sized enterprises (SMEs), research labs, and educational institutions.

Chinese manufacturers are actively innovating and developing small reflow soldering machines to meet the diverse needs of the market. These machines are designed to offer compact size, precise temperature control, user-friendly interfaces, and cost-effectiveness, making them suitable for a wide range of applications, including prototyping, low to medium volume production, and small-scale research projects. Additionally, manufacturers are focusing on enhancing the efficiency, reliability, and performance of these machines to meet the stringent quality standards of the electronics industry.

The competitive landscape in China's small reflow soldering machine market is characterized by a mix of domestic and international players, with both established companies and emerging startups vying for market share. Chinese manufacturers benefit from lower production costs, economies of scale, and proximity to the vast domestic market, allowing them to offer competitive pricing and flexible customization options to customers. Moreover, the government's support for technological innovation and industrial development further stimulates growth and innovation in the sector.

Manufacturing Hub: China is one of the world's largest manufacturers of electronics and electronic components. It has a vast network of factories, ranging from large-scale production facilities to smaller contract manufacturers, all of which require soldering equipment for PCB assembly.

Market Demand: With the rapid growth of consumer electronics, IoT devices, automotive electronics, and other electronic products, there is a substantial demand for reflow soldering machines in China. This demand spans across various industries, including telecommunications, automotive, consumer electronics, and industrial equipment.

Local Production: China has a robust manufacturing infrastructure for producing reflow soldering machines domestically. Many Chinese companies specialize in manufacturing soldering equipment, including both large-scale reflow ovens for mass production and smaller, benchtop reflow soldering machines suitable for prototyping and small-scale production.

Technological Advancements: Chinese manufacturers of reflow soldering machines are continually innovating to stay competitive in the global market. They invest in research and development to improve the performance, efficiency, and reliability of their machines. This includes advancements in temperature control, conveyor systems, flux management, and user interface features.

Competitive Landscape: The market for reflow soldering machines in China is highly competitive, with both domestic manufacturers and international brands vying for market share. Chinese companies often offer competitive pricing and tailor their products to meet the specific needs of local customers.

Export Market: In addition to serving domestic demand, Chinese manufacturers of reflow soldering machines also export their products to international markets. This export-oriented approach has helped Chinese companies expand their presence globally and establish themselves as major players in the soldering equipment industry.

Regulatory Environment: Chinese manufacturers must adhere to domestic and international regulations governing the production and sale of soldering equipment. This includes compliance with safety standards, environmental regulations, and export/import requirements.

The situation of small reflow soldering machines in China is characterized by robust manufacturing capabilities, strong market demand, technological innovation, and fierce competition. This dynamic environment ensures a wide range of options for customers seeking soldering equipment for various applications.