Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Common Challenges in AOI Testing and Effective Strategies to Overcome Them

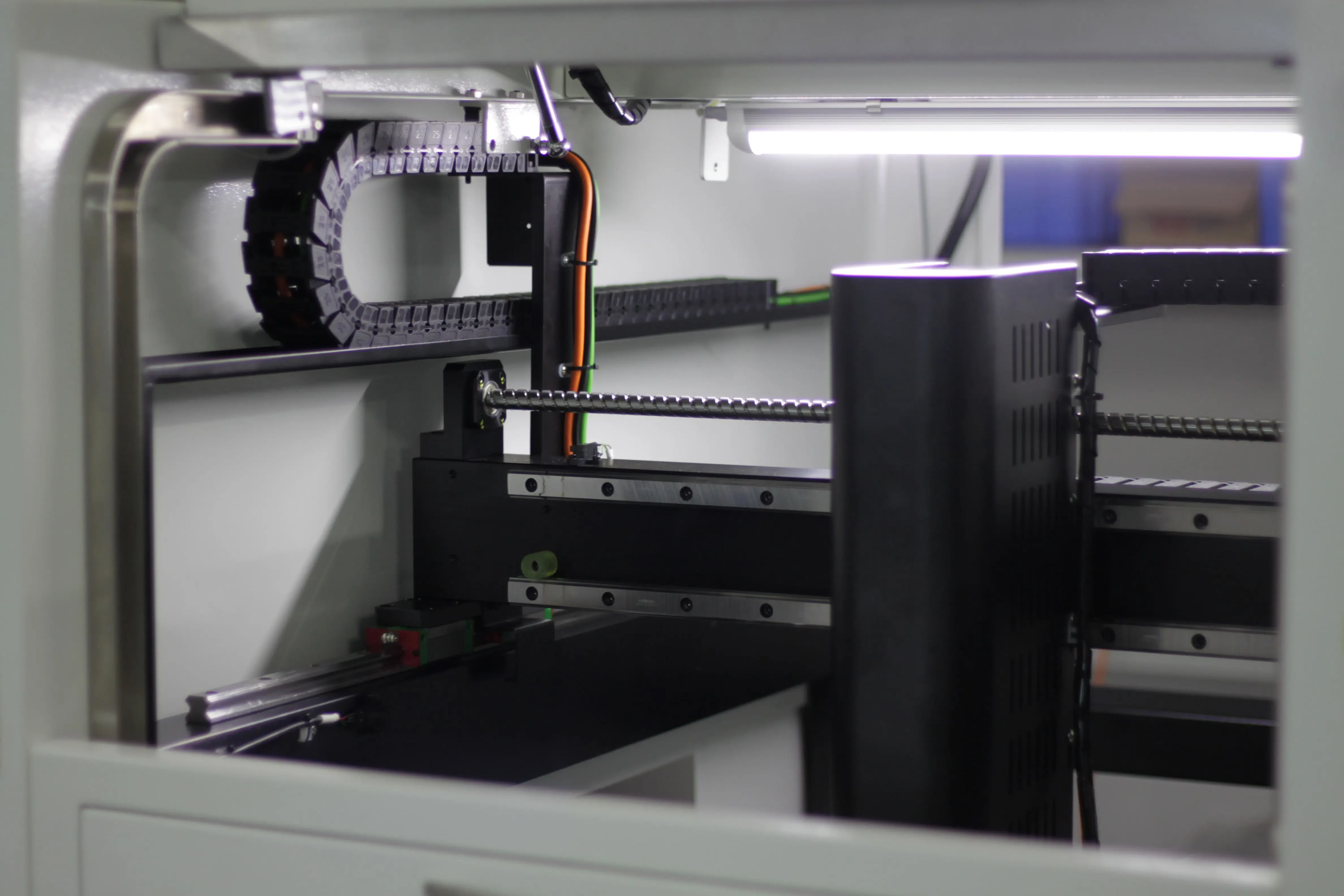

AOI (Automated Optical Inspection) Testing is a critical process in the manufacturing industry that ensures product quality and reliability. However, like any complex system, AOI Testing may encounter challenges that can impact its effectiveness. In this blog post, we will explore some common challenges faced during AOI Testing and provide effective strategies to overcome them. By understanding and addressing these challenges, manufacturers can optimize their AOI Testing processes, improve inspection outcomes, and maintain high-quality standards in their products.

One of the significant challenges in AOI Testing is dealing with false positives and false negatives. False positives occur when the system flags a component as defective when it is not, leading to unnecessary rework or waste. False negatives, on the other hand, occur when the system fails to detect an actual defect, allowing faulty components to pass inspection. To overcome these challenges, manufacturers can implement strategies such as:

- Calibration and Optimization: Regular calibration and optimization of the AOI system can help minimize false positives and false negatives. This involves adjusting the inspection parameters, lighting conditions, and image processing algorithms to achieve the optimal balance between sensitivity and accuracy.

- Sample Training and Verification: Training the AOI system on a representative sample of good and defective components can enhance its ability to accurately distinguish between acceptable and faulty products. Verification of the system's performance using known defect samples can help fine-tune its settings and reduce false results.

2. Complex Component Variations:

Modern manufacturing involves producing complex components with intricate designs, multiple layers, and miniature features. AOI Testing may face challenges in accurately inspecting these components due to their intricate nature. To overcome this challenge, manufacturers can employ the following strategies:

- Adaptive Algorithms and Machine Learning: Implementing adaptive algorithms and machine learning techniques can enhance the AOI system's ability to adapt and recognize complex component variations. By continuously learning from previous inspections, the system can improve its accuracy in detecting defects and variations in different component designs.

- Multiple Angled Cameras and Lighting: Using multiple angled cameras and lighting setups can provide comprehensive coverage of complex components. This allows the AOI system to capture different perspectives and details that may not be visible from a single viewpoint, improving inspection accuracy.

3. High-Speed Inspection:

In fast-paced manufacturing environments, high-speed inspection is essential to maintain production efficiency. However, conducting AOI Testing at high speeds can present challenges in capturing accurate images and processing them in real-time. To address this challenge, manufacturers can consider the following strategies:

- High-Speed Imaging Systems: Investing in high-speed imaging systems specifically designed for AOI Testing can enable accurate image capture even at high production speeds. These systems offer faster frame rates and advanced image processing capabilities to handle the rapid pace of manufacturing.

- Parallel Processing and Hardware Optimization: Implementing parallel processing techniques and optimizing hardware resources can enhance the AOI system's speed and efficiency. Distributing processing tasks across multiple processors or utilizing dedicated hardware accelerators can significantly reduce inspection time and maintain high-speed performance.

Conclusion:

AOI Testing plays a vital role in ensuring product quality and reliability in the manufacturing industry. By acknowledging and addressing the common challenges faced in AOI Testing, manufacturers can optimize their inspection processes and improve outcomes. Strategies such as reducing false positives and false negatives, adapting to complex component variations, and implementing high-speed inspection techniques can enhance the effectiveness and efficiency of AOI Testing. By overcoming these challenges, manufacturers can maintain high-quality standards, reduce rework, and deliver reliable products to their customers.