Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Conveyor Efficiency: Expert Distribution Insights

Introduction:

In the dynamic landscape of industrial automation, "automated conveyor systems distributors" play a pivotal role in ensuring seamless and efficient material handling. These systems, widely employed in manufacturing, warehousing, and distribution, have evolved to meet the diverse needs of businesses striving for enhanced productivity and cost-effectiveness.

I. Understanding the Landscape of Automated Conveyor Systems

Automated conveyor systems, often hailed as the backbone of modern industries, encompass a spectrum of solutions. Gravity conveyors, with their simplicity and reliability, facilitate the smooth flow of goods, particularly in distribution centres where speed and precision are paramount. Belt conveyors, known for their versatility, find applications across industries, providing a conveyor belt of possibilities for manufacturers seeking efficiency.

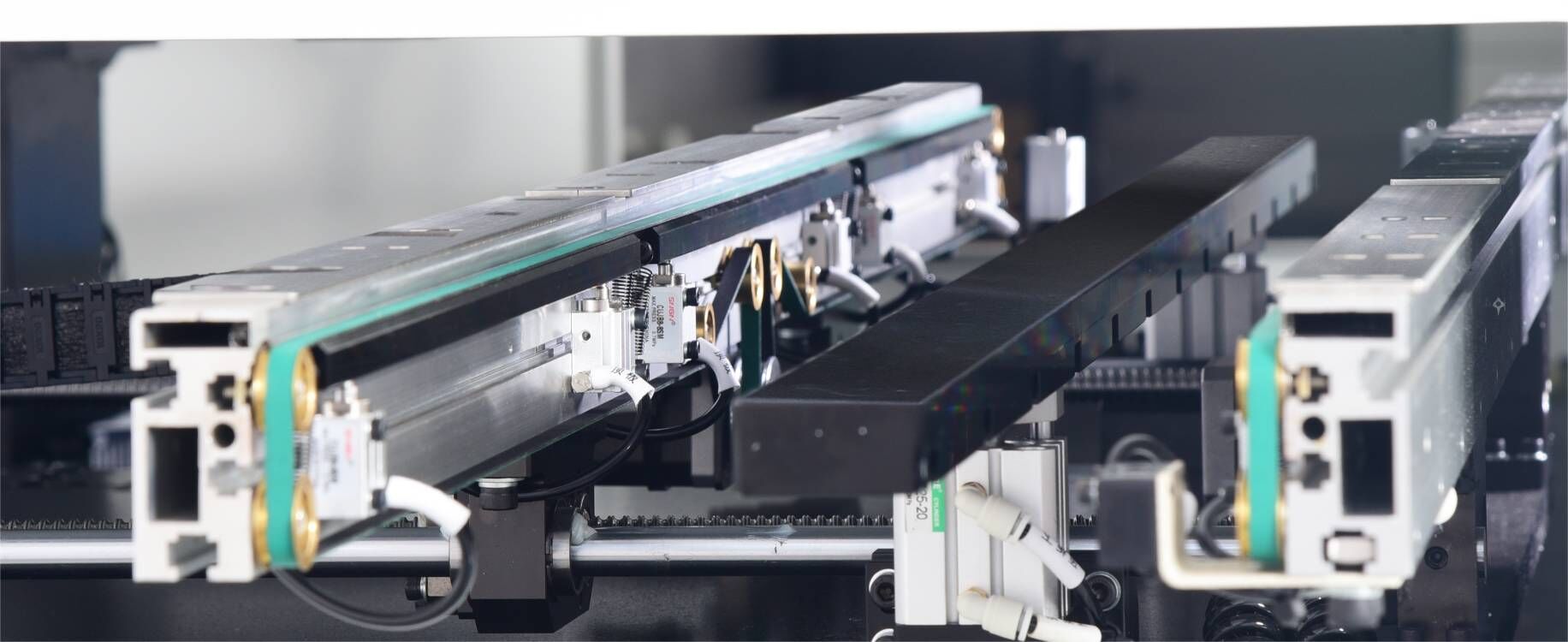

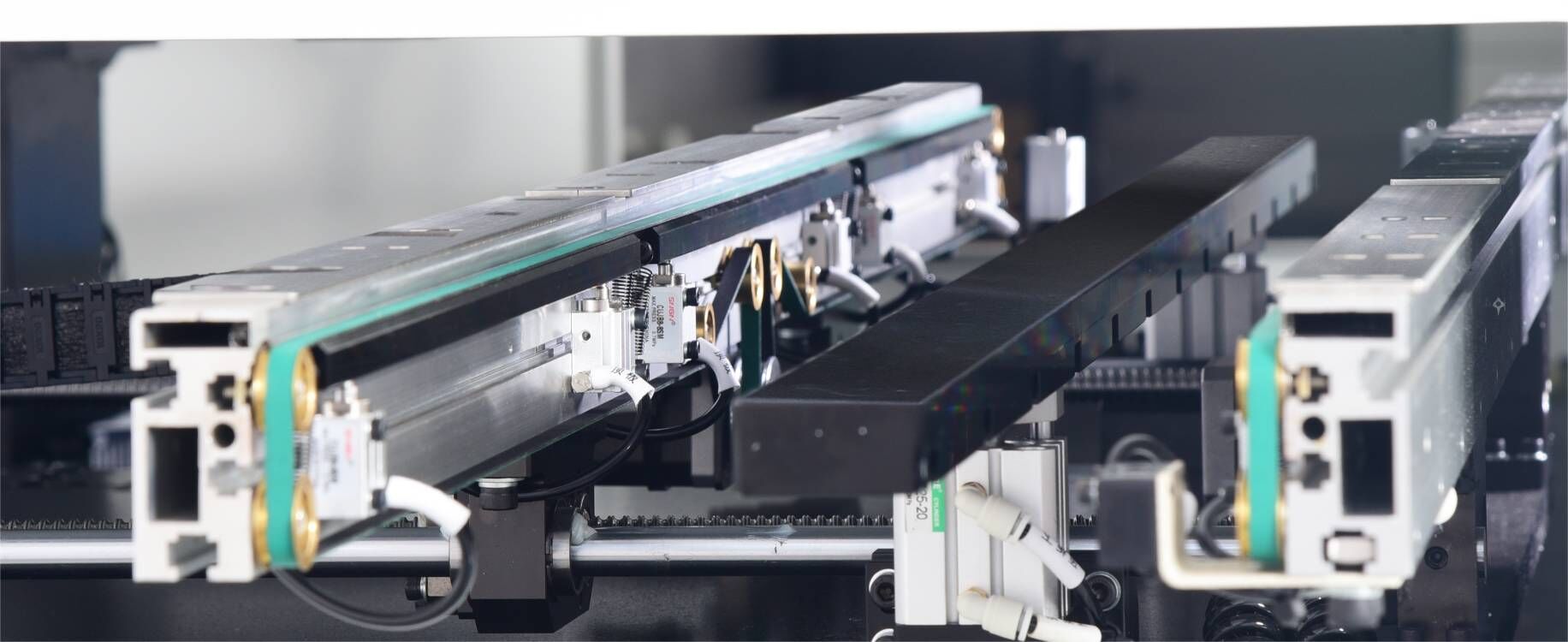

II. Roller Conveyors: Navigating Efficiency with Precision

Roller conveyors, characterised by their dynamic functionality, are embraced for their ability to handle various load sizes. Distributors specialising in roller conveyor systems bring expertise in optimising these conveyors, ensuring a harmonious blend of efficiency and adaptability.

III. Overhead Conveyors: Elevating Possibilities in Material Handling

The realm of overhead conveyors introduces a vertical dimension to material transport. These systems, distributed by seasoned professionals, find their niche in industries where space optimisation is critical. Distributors, cognizant of the unique challenges posed by overhead conveyors, navigate the complexities with finesse, offering turnkey solutions for businesses aiming for elevated efficiency.

IV. Automated Guided Vehicles (AGVs): Pioneering Autonomy in Movement

As we delve into the future of material handling, the integration of automated guided vehicles (AGVs) emerges as a transformative trend. These self-guided vehicles, expertly distributed by key players in the industry, embody the synergy between robotics and conveyance, seamlessly navigating manufacturing floors and distribution centres. Distributors bring a holistic approach, aligning AGV implementation with Industry 4.0 principles.

V. Selecting the Ideal Conveyor System: A Collaborative Effort

Choosing the right conveyor system is a nuanced process, demanding a meticulous evaluation of various factors. Distributors, functioning as knowledge partners, collaborate with businesses to customise conveyor solutions tailored to unique needs. Synthesising perspectives from engineering, logistics, and technology, these distributors ensure a holistic approach, delivering systems that seamlessly integrate with existing operations.

VI. Future Horizons: Innovations and Sustainable Trends

The future of automated conveyor systems lies in the confluence of innovation and sustainability. Industry leaders and distributors actively explore eco-friendly materials and energy-efficient technologies, aligning with global initiatives for a greener tomorrow. As we traverse into an era marked by interconnected systems, the integration of IoT and real-time data analytics into conveyor systems becomes a focal point for distributors aiming to stay ahead of the curve.

Conclusion:

In conclusion, the world of "automated conveyor system distributors" is a vibrant tapestry of innovation and efficiency. Navigating this landscape requires an understanding of the diverse systems available, the expertise of distributors, and a keen eye on future trends. As businesses continue to seek streamlined operations, these conveyor systems, distributed by knowledgeable professionals, stand as the conduit between traditional practices and the future of industrial automation.