Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

High-Quality Industrial SMT Related Machines

Introduction: The Pulse of Modern Technology

In the heartbeat of modern technology lies the intricate world of electronics manufacturing, where precision meets innovation. At the core of this world are the high-quality industrial SMT (Surface Mount Technology) machines that transform raw components into sophisticated devices. These machines are not just tools; they are the architects of the future, crafting the devices that power our lives.

As we look ahead, the evolution of SMT machines promises to redefine efficiency, precision, and innovation in electronics manufacturing.

The Backbone of Electronics: SMT Machines

SMT machines are the backbone of the electronics manufacturing process, enabling the creation of everything from smartphones to complex medical devices. Their high-quality performance ensures that every component is placed with microscopic accuracy, leading to products that are reliable and efficient.

Why High-Quality Matters

Quality in SMT machines is not a luxury; it's a necessity. High-quality machines reduce defects, improve yields, and ensure that products meet the stringent demands of consumers and industries alike.

Working Principle of SMT Machines

The SMT process involves mounting electronic components directly onto the surface of printed circuit boards (PCBs). This is achieved through a series of steps, including solder paste printing, component placement, and reflow soldering. The precision and speed of SMT machines are crucial for the successful assembly of electronic devices.

The Workhorses of the SMT Process

1. Solder Paste Printing Machines: The Foundation

The journey of an electronic device begins with the solder paste printing machine. This automated system meticulously applies the right amount of solder paste onto the PCB, setting the stage for component placement. The precision of this machine is the first guarantee of a well-assembled product.

2. Solder Paste Inspection (SPI) Machines: The Guardians

No process is too small to escape the watchful eye of the SPI machine. These guardians of the SMT process ensure that the solder paste application is flawless, identifying and correcting any imperfections before they become bigger issues.

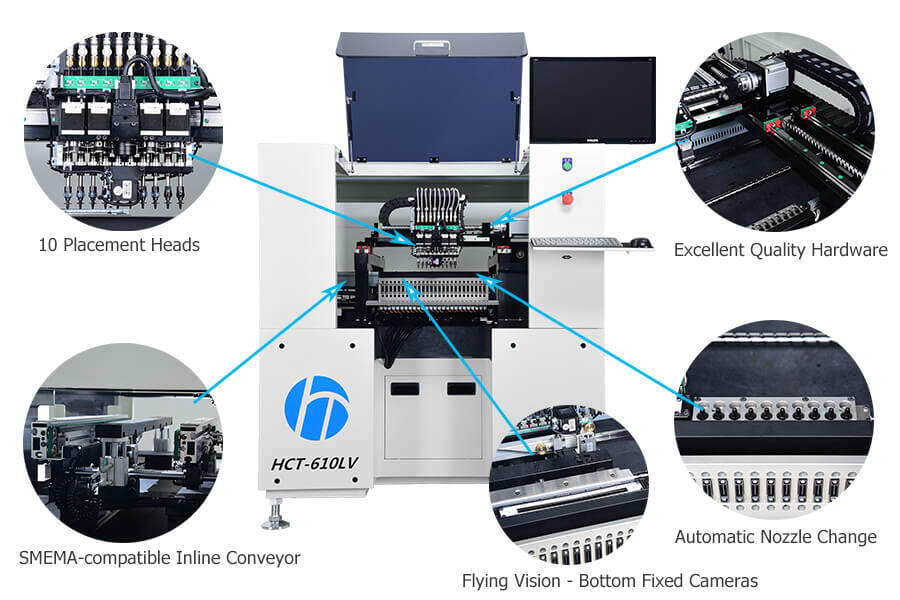

3. Pick and Place Machines: The Choreographers

The pick and place machines are the choreographers of the SMT assembly line, picking up components and placing them in their designated locations with balletic grace. Whether manual, semi-automatic, or fully automatic, these machines ensure that every component finds its perfect spot on the PCB.

a. Manual Precision

Manual machines rely on the skilled hands of operators, offering flexibility but requiring a high level of expertise.

b. Semi-Automatic Synergy

Semi-automatic machines blend human intuition with machine precision, providing a harmonious balance between the two for enhanced accuracy.

c. Automatic Excellence

Automatic machines represent the pinnacle of SMT technology, offering unparalleled speed and accuracy that redefine efficiency in electronics manufacturing.

4. Reflow Soldering Machines: The Binders

After components are placed, reflow soldering machines take over, melting the solder paste to create strong, conductive bonds. These binders ensure that each SMD is firmly attached, contributing to the structural integrity of the final product.

This machine is essential for permanently attaching surface mount devices to a printed circuit board. It preheats the components and then melts the solder paste to form strong and long-lasting joints between the SMDs and the circuit board, all without causing any heat damage to the delicate SMDs.

5. PCB Inspection Equipment: The Critics

The critics of the SMT process, PCB inspection equipment, scrutinize every detail of the circuit board, identifying defects before they can affect the final product. Their precision and accuracy are the final line of defense in ensuring product quality.

Highly sophisticated SMT machines designed for inspecting and repairing printed circuit boards. These machines not only identify potential defects or faults on the circuit board but also aid in repairing and fixing them. The thorough inspection of the PCB is guaranteed by highly precise and accurate measurements.

Leading the Charge: Top Manufacturers of SMT Machines

Yamaha Motor: The Innovators

Yamaha Motor leads with a comprehensive range of SMT machines designed to optimize production efficiency and reliability, setting the bar high for electronic assembly.

FUJI CORPORATION: The Precision Masters

FUJI CORPORATION is synonymous with high-speed, high-precision SMT machines that ensure consistent quality, making them a favorite among manufacturers with stringent requirements.

Panasonic: The Versatile Choice

Panasonic offers a variety of SMT machines capable of handling diverse components and PCB sizes, making them a versatile choice for manufacturers with varied production needs.

DDM Novastar: The Budget-Friendly Experts

DDM Novastar provides affordable, easy-to-use, and reliable SMT machines, making high-quality electronics manufacturing accessible to a broader range of businesses.

The Global Reach of High-Quality SMT Machines

High-quality industrial SMT machines are not confined to a single region; they have a global reach. Manufacturers from China, such as HCT, are exporting their products worldwide, emphasizing quality, efficiency, and customer satisfaction.

The Future of SMT Machines: Innovations on the Horizon

As technology advances, we can expect improvements in SMT machine technology, such as more energy-efficient LEDs, smarter curing systems, and potentially, integration with mobile apps for personalized settings.

1. Smart Integration

Expect to see SMT machines with integrated smart technology, such as Bluetooth connectivity for app-controlled settings, enhancing user experience and customization.

2. Eco-Friendly Design

With growing environmental concerns, the future may hold SMT machines designed with sustainability in mind, using energy-efficient components and recyclable materials.

3. Advanced Automation

The integration of robotics and artificial intelligence in SMT machines will likely lead to further automation, reducing the need for manual intervention and increasing production efficiency.

Market Trends and Opportunities

The market for SMT machines is dynamic, with a clear trend towards smarter and more efficient fixtures. Understanding these trends is crucial for businesses looking to invest in this technology.

1. Demand for Miniaturization

As electronic devices become smaller and more compact, the demand for SMT machines capable of handling smaller components with high precision is on the rise.

2. Growth in Emerging Markets

The electronics manufacturing industry is expanding rapidly in emerging markets, creating new opportunities for SMT machine manufacturers to cater to these growing markets.

3. Technological Advancements

Continuous advancements in SMT technology are driving the need for updated machines that can keep pace with the latest electronic components and assembly requirements.

Conclusion: The Heart of Electronics Manufacturing

In the intricate dance of electronics manufacturing, high-quality industrial SMT machines are the heart that pumps life into every device. As technology continues to evolve, the demand for precision, efficiency, and reliability in SMT machines will only grow. For manufacturers, the choice of SMT machines is not just about producing a product; it's about shaping the future of technology.