Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Mastering Hot Glue Dispensing Machines: Your Ultimate Guide

Hot glue dispensing machines have revolutionized adhesive application across industries, offering unmatched precision and efficiency. In this comprehensive guide, we will delve into the intricacies of hot glue dispensing machines, exploring their functionalities, applications, key features, reputable suppliers, best practices, and more. By the end, you'll be equipped with the knowledge to harness the full potential of these machines and elevate your adhesive dispensing processes to new heights.

Understanding Hot Glue Dispensing Machines

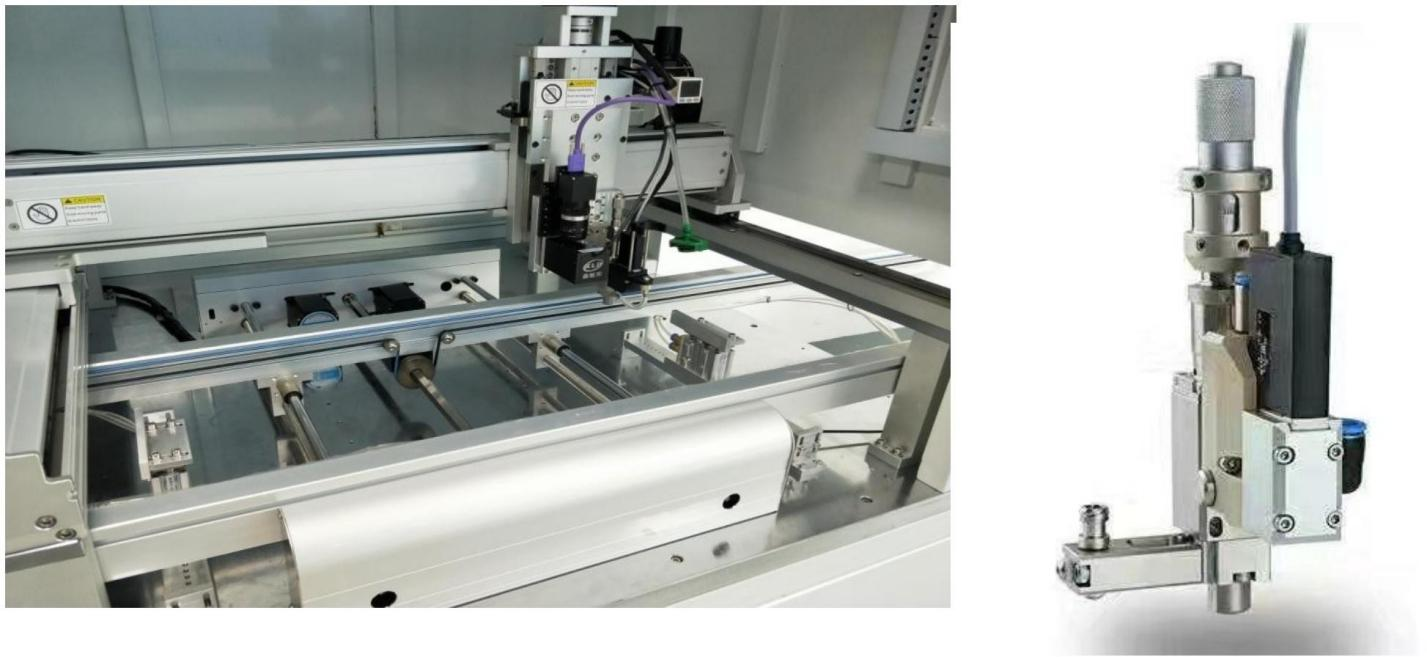

Hot glue dispensing machines, also known as hot melt adhesive dispensers, are sophisticated devices engineered to precisely dispense hot melt adhesive onto surfaces. These machines typically consist of a heated reservoir, a dispensing mechanism (such as a nozzle or applicator), and control systems for regulating temperature and flow rate. The adhesive, typically in solid form, is heated to a molten state within the reservoir and then dispensed onto the desired surface through the dispensing mechanism.

Applications of Hot Glue Dispensing Machines

The versatility lends itself to a myriad of applications across various industries:

1. Packaging: In packaging operations, hot glue dispensers are used to seal boxes, cartons, and packages securely. The precise application of adhesive ensures product integrity during shipping and handling.

2. Automotive: Automotive manufacturers rely on the dispensing machines for bonding trim components, insulating materials, and securing wiring harnesses. The robust bonds created by hot melt adhesive contribute to the durability and reliability of vehicles.

3. Electronics: Hot glue dispensers play a critical role in the electronics industry by potting electronic components, securing connectors, and encapsulating sensitive parts. The adhesive properties of hot melt adhesive provide protection against environmental factors and mechanical stress.

4. Textiles: In textile manufacturing, the dispensing machines are utilized for bonding fabrics, attaching labels, and creating intricate designs. The precise application of adhesive enhances production efficiency and product quality.

5. Construction: In the construction sector, hot glue dispensers are used for bonding materials such as wood, plastic, and foam insulation. The fast-setting nature of hot melt adhesive facilitates rapid assembly and construction processes.

Key Features to Consider

When selecting a hot glue dispensing machine, several key features should be carefully evaluated to ensure optimal performance:

1. Dispensing Speed and Precision: Look for machines that offer adjustable dispensing speed and precise control over adhesive flow. The ability to fine-tune dispensing parameters enables tailored adhesive application for specific requirements.

2. Heating System: The efficiency and reliability of the heating system are paramount to maintaining consistent adhesive viscosity and temperature. A robust heating system ensures uninterrupted operation and reliable adhesive flow.

3. Dispensing Mechanism: Evaluate the dispensing mechanism, including nozzle types, dispensing patterns, and automation capabilities. The choice of dispensing mechanism should align with the application requirements to achieve desired bonding results.

4. Compatibility: Consider the compatibility of the machine with different types and viscosities of adhesive materials. A versatile machine capable of accommodating various adhesive formulations ensures flexibility and adaptability in adhesive application.

5. Safety Features: Prioritize machines equipped with comprehensive safety features to protect both operators and equipment. Safety features such as overheat protection, emergency stop buttons, and interlock systems mitigate potential hazards and ensure safe operation.

Exploring Hot Glue Dispensing Machine Suppliers

1. ABC Adhesive Solutions: ABC offers a diverse range renowned for their reliability, precision, and customizable features. Their commitment to customer satisfaction and technical support ensures a seamless experience from procurement to operation.

2. XYZ Industrial Equipment: XYZ specializes in high-speed dispensing machines tailored for large-scale manufacturing operations. With advanced automation and precision control systems, XYZ machines deliver unparalleled performance and efficiency in adhesive application.

3. DEF Engineering Solutions: DEF provides compact and versatile dispensing machines suitable for small businesses and workshops. Their user-friendly designs and flexible configurations empower users to achieve precise and consistent adhesive dispensing with ease.

4. GHI Automation Technologies: GHI offers cutting-edge dispensing machines equipped with innovative features such as robotic integration and IoT connectivity. Their commitment to technological advancement and industry expertise positions them as a preferred supplier for automated adhesive dispensing solutions.

Best Practices for Hot Glue Dispensing

1. Material Preparation: Properly store adhesive materials and ensure they are heated to the recommended temperature before dispensing to maintain optimal viscosity and flow characteristics.

2. Surface Preparation: Thoroughly clean and dry surfaces to be bonded to remove any contaminants or debris, promoting strong adhesion and preventing potential bond failure.

3. Testing and Calibration: Regularly test and calibrate dispensing machines to maintain accuracy and consistency in adhesive application, minimizing variability and ensuring reliable bonding results.

Conclusion

Hot glue dispensing machines represent the epitome of efficiency and precision in adhesive application, revolutionizing manufacturing processes across industries. By understanding their functionalities, applications, key features, reputable suppliers, and best practices, you can harness the full potential of these machines to streamline production processes, enhance product quality, and achieve superior bonding results. With the right knowledge and resources at your disposal, mastering hot glue dispensing becomes an attainable goal, empowering you to excel in adhesive dispensing endeavors.