Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

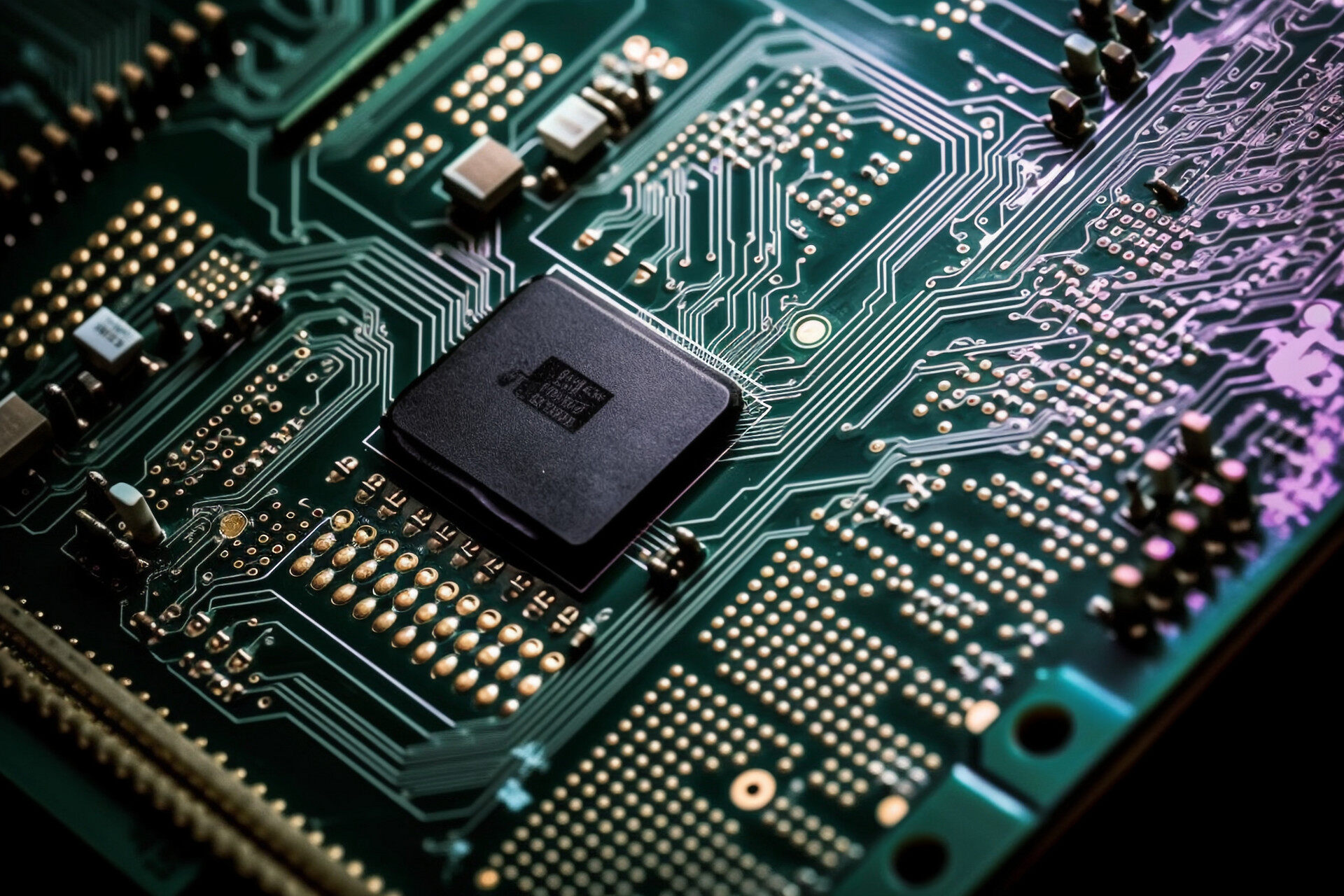

Pcb Component Placement Machine

A PCB component placement machine, also known as a pick-and-place machine or a surface mount technology (SMT) machine, is an essential tool used in the assembly of printed circuit boards (PCBs). These machines automate the process of accurately placing electronic components onto PCBs, enhancing production efficiency and consistency.

Key Components:

- Feeder System: Holds and supplies electronic components to the placement head.

- Placement Head: Picks up components from feeders and precisely places them onto designated locations on the PCB.

- Vision System: Provides visual recognition to ensure accurate component alignment and placement.

- Conveyor System: Transports PCBs through the assembly process, synchronizing with the placement head for precise component placement.

- Software Control Interface: Allows operators to program placement sequences, adjust parameters, and monitor the machine's operation.

Working Principle:

- Component Feeding: Electronic components are loaded into feeders and organized according to the PCB's assembly requirements.

- Vision Inspection: The PCB is typically scanned to identify fiducial marks or other alignment features, enabling precise component placement.

- Component Pickup: The placement head retrieves components from the feeders based on programmed instructions.

- Placement: Components are accurately placed onto the PCB according to the design layout, guided by the vision system.

- Reflow Soldering: After component placement, the PCB undergoes reflow soldering to permanently affix the components to the board.

Types of Placement Machines:

- High-Speed Chip Shooters: Designed for high-volume production, these machines specialize in placing small, lightweight components such as resistors and capacitors at high speeds.

- Flexible Placement Machines: These machines offer versatility for handling a wide range of component sizes and types, including larger and odd-shaped components.

- Multi-Head Placement Machines: Equipped with multiple placement heads, these machines can simultaneously pick and place multiple components, improving throughput.

- Desktop Placement Machines: Compact and cost-effective machines suitable for prototyping, small-batch production, or low-volume assembly.

Benefits:

- Improved Efficiency: Automates the component placement process, reducing manual labor and assembly time.

- Accuracy and Consistency: Ensures precise component alignment and placement, minimizing errors and improving product quality.

- Versatility: Can handle various component sizes, types, and package styles, enhancing manufacturing flexibility.

- Increased Throughput: Enables higher production volumes compared to manual assembly methods, supporting scalability.

- Reduced Costs: Optimizes production efficiency and minimizes rework, contributing to overall cost savings.

Considerations for Selection:

- Production Volume: Choose a machine suitable for the expected production volume, considering throughput requirements.

- Component Compatibility: Ensure the machine can handle the types and sizes of components used in your PCB designs.

- Accuracy and Speed: Evaluate the machine's placement accuracy and speed capabilities to meet production demands.

- Flexibility: Assess the machine's ability to adapt to changing production needs and accommodate future requirements.

- Ease of Use and Maintenance: Consider user-friendly features and maintenance requirements to streamline operation and minimize downtime.

In summary, PCB component placement machines play a crucial role in modern electronics manufacturing, offering automation, precision, and efficiency in the assembly of printed circuit boards. Selecting the right machine involves evaluating factors such as production volume, component compatibility, accuracy, flexibility, and ease of use to meet specific manufacturing requirements.