Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

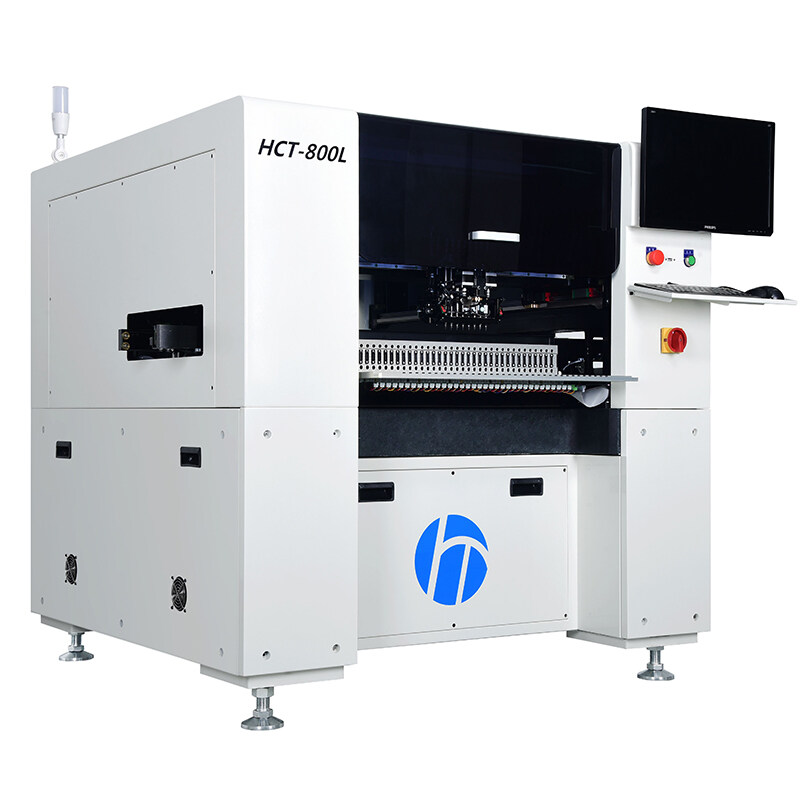

Precision in Every Placement: Navigating Electronics Assembly with SMT Manual Pick and Place Machine

In the dynamic landscape of electronics manufacturing, the SMT manual pick and place machine emerges as a versatile solution, offering a hands-on approach to component assembly. This blog post aims to explore the distinctive features and advantages of the SMT manual pick and place machine, emphasizing its role in providing flexibility, cost-effectiveness, and precision in the assembly process.

The SMT manual pick and place machine stands as a testament to adaptability in electronics assembly. Unlike its automated counterparts, this machine offers a hands-on, operator-controlled approach to component placement. This blog post seeks to unravel the unique attributes and benefits of the SMT manual pick and place machine, highlighting its significance in scenarios where flexibility and precision are paramount.

Hands-On Component Placement:

At the core of the SMT manual pick and place machine is the hands-on component placement process. Operators have direct control over the placement of electronic components onto printed circuit boards (PCBs). This tactile approach allows for a more intimate understanding of the assembly process, enabling operators to ensure precision in component positioning.

Versatility in Component Handling:

One of the key advantages of the SMT manual pick and place machine lies in its versatility in handling various electronic components. From resistors and capacitors to integrated circuits, operators can delicately handle a diverse range of components with different sizes and form factors. This adaptability is particularly beneficial in environments where assembly requirements vary across different projects.

Cost-Effectiveness and Accessibility:

In scenarios where high-volume automated solutions may be economically impractical, the SMT manual pick and place machine shines as a cost-effective alternative. The initial investment and operational costs are generally lower, making it accessible to a broader range of manufacturers, especially small to medium-sized enterprises. This cost-effectiveness contributes to the machine's popularity in settings with diverse budget considerations.

The SMT manual pick and place machine places a premium on the expertise and skill of operators. Trained operators can leverage their knowledge to optimize the assembly process, ensuring precise component placements. This reliance on operator skill fosters a sense of craftsmanship, where the human touch plays a crucial role in achieving the desired quality in electronic assemblies.

Flexible Production Runs and Changeovers:

Flexibility is a hallmark of the SMT manual pick and place machine. Operators can easily adapt to changes in production runs and quickly switch between different projects. This flexibility is especially advantageous in environments where the production landscape is dynamic, allowing manufacturers to efficiently respond to varying assembly requirements without significant downtime.

Ideal for Prototyping and Low-Volume Production:

In scenarios involving prototyping or low-volume production, the SMT manual pick and place machine proves to be an ideal choice. Its flexibility, cost-effectiveness, and hands-on nature make it well-suited for environments where the emphasis is on developing prototypes or producing smaller batches of electronic devices with specialized requirements.

Precision Control and Customization:

The SMT manual pick and place machine provides operators with precision control over the placement of components. This level of control is particularly valuable when customization is a priority. Operators can fine-tune the placement of components according to specific design requirements, ensuring a high degree of customization in the assembly process.

Operator-Centric Quality Assurance:

Quality assurance takes on an operator-centric approach with the SMT manual pick and place machine. Operators can visually inspect each component placement, ensuring that it aligns with quality standards. This hands-on quality assurance process contributes to the production of high-quality electronic assemblies, meeting the stringent requirements of the electronics industry.

Conclusion:

In conclusion, the SMT manual pick and place machine brings a human touch to electronics assembly, offering a flexible, cost-effective, and precision-oriented solution. Its emphasis on hands-on component placement, versatility, cost-effectiveness, operator expertise, flexibility in production runs, suitability for prototyping, precision control, and operator-centric quality assurance set it apart in environments where adaptability and customization are paramount. Embrace the precision in every placement with the SMT manual pick and place machine – where operator skill meets flexibility, and innovation thrives in the hands-on approach to electronics assembly.