Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Please enter the email address you’d like your password reset information sent to.

Email format error

Email cannot be empty

Email does not exist

Reset account password

For the account

6-20 characters(letters plus numbers only)

The password is inconsistent

Reset success

Your password was reset. You can log in using your new password.

Login

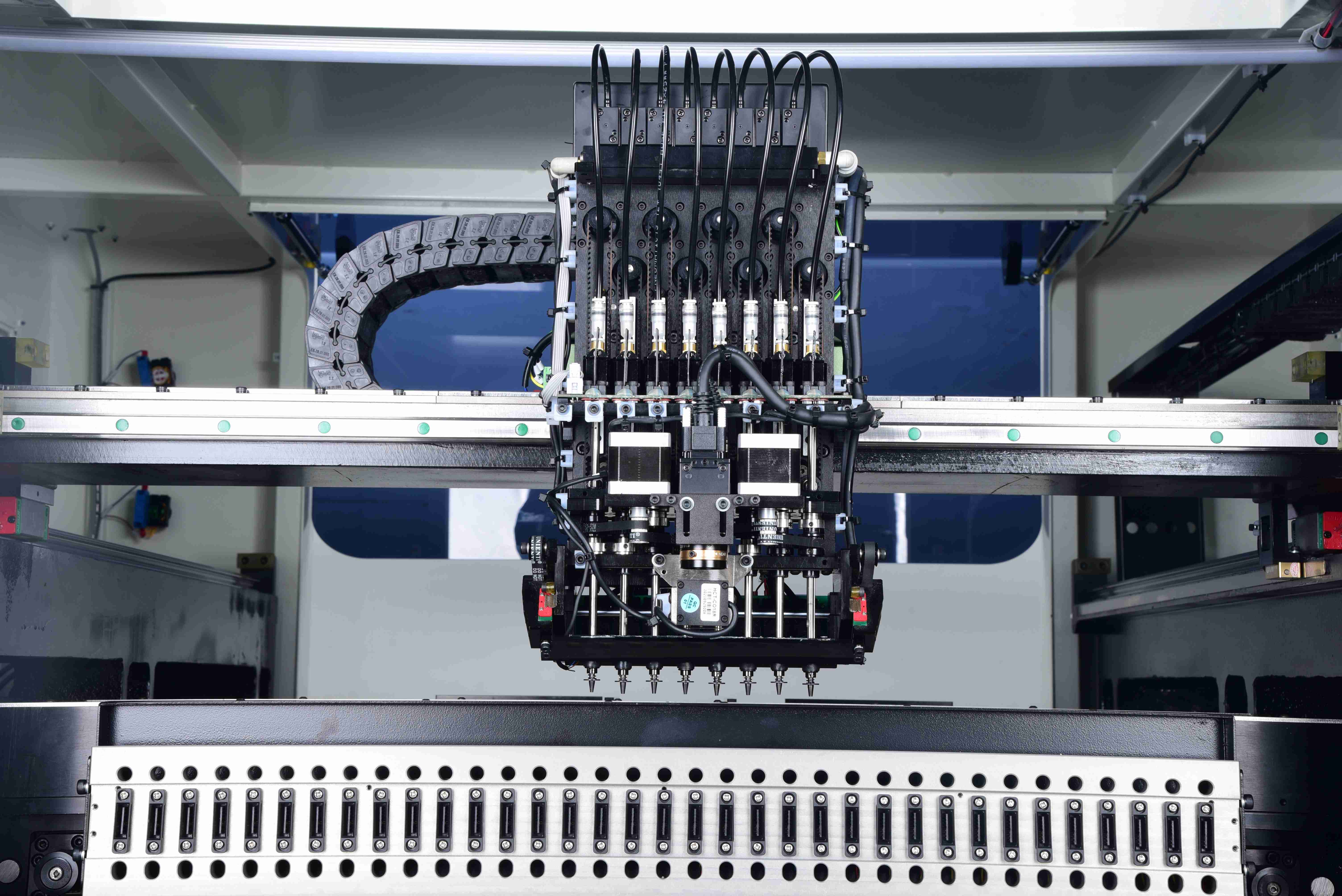

The Multifunctional Basic Pick and Place Machine: Revolutionizing Manufacturing Efficiency

2023-09-19 15:00:27

In manufacturing industry, efficiency and productivity are paramount. To meet these demands, the multifunctional basic pick and place machine has emerged as a game-changer. This advanced technology offers a wide range of capabilities, making it an indispensable tool for manufacturers worldwide. In this blog post, we will explore the various features and benefits of this innovative machine and how it can revolutionize your manufacturing processes.

I. The Power of Multifunctionality:

1.1 Versatility at its Best:

The multifunctional basic pick and place machine is designed to handle a diverse range of tasks, from component placement to soldering and inspection. Its ability to adapt to different manufacturing requirements makes it an invaluable asset for any production line.

1.2 Streamlined Workflow:

By integrating multiple functions into a single machine, manufacturers can eliminate the need for separate equipment, reducing setup time and optimizing workflow. This streamlining effect translates into significant time and cost savings, ultimately boosting overall productivity.

II. Precision and Accuracy:

2.1 Automated Component Placement:

With its advanced vision system and robotic arms, the pick and place machine ensures precise and accurate component placement. This eliminates the risk of human error and guarantees consistent quality throughout the manufacturing process.

2.2 High-Speed Operation:

Equipped with cutting-edge technology, the machine operates at high speeds, significantly increasing production rates. Its ability to handle complex tasks swiftly and accurately enhances efficiency, allowing manufacturers to meet tight deadlines and customer demands.

III. Enhanced Quality Control:

3.1 Real-Time Inspection:

The pick and place machine incorporates real-time inspection capabilities, ensuring that each component is correctly placed and soldered. This proactive approach to quality control minimizes the risk of defects and reduces the need for rework, saving both time and resources.

3.2 Traceability and Data Analysis:

By capturing and analyzing data during the manufacturing process, the machine enables manufacturers to identify potential issues and implement corrective measures promptly. This data-driven approach enhances product quality and customer satisfaction, ultimately strengthening the brand’s reputation.

Conclusion:

In conclusion, the multifunctional basic pick and place machine is a game-changer in the manufacturing industry. Its versatility, precision, and enhanced quality control capabilities make it an indispensable tool for manufacturers seeking to optimize their production processes. By investing in this advanced technology, manufacturers can achieve higher productivity, reduced costs, and improved customer satisfaction.

As a leading supplier of multifunctional basic pick and place machines, we are committed to providing cutting-edge solutions that empower manufacturers to thrive in today’s competitive market. Contact us today to learn more about how our machines can revolutionize your manufacturing efficiency and take your business to new heights.

Contact us