Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Advancing Manufacturing Excellence: China's SMT Full Automatic LED Production Line

Surface Mount Technology (SMT) has revolutionized the LED manufacturing process, enabling higher precision, increased efficiency, and reduced costs. China has emerged as a global leader in this field, with its full automatic LED production lines showcasing cutting-edge technology and innovation. This article will delve into the details of the SMT full automatic LED production line, analyze its significance from various angles, and shed light on the advantages and prospects of Chinese producers in this competitive industry.

1. Understanding the SMT Full Automatic LED Production Line:

The SMT full automatic LED production line is an advanced manufacturing system that seamlessly integrates multiple machines to produce LED components and assemblies. The line comprises various stages, including solder paste application, pick-and-place machines for component placement, reflow ovens for soldering, and inspection systems to ensure product quality.

Key components of the production line:

a) Solder Paste Printer: Precisely applies solder paste to the PCBs, enhancing soldering accuracy during component placement.

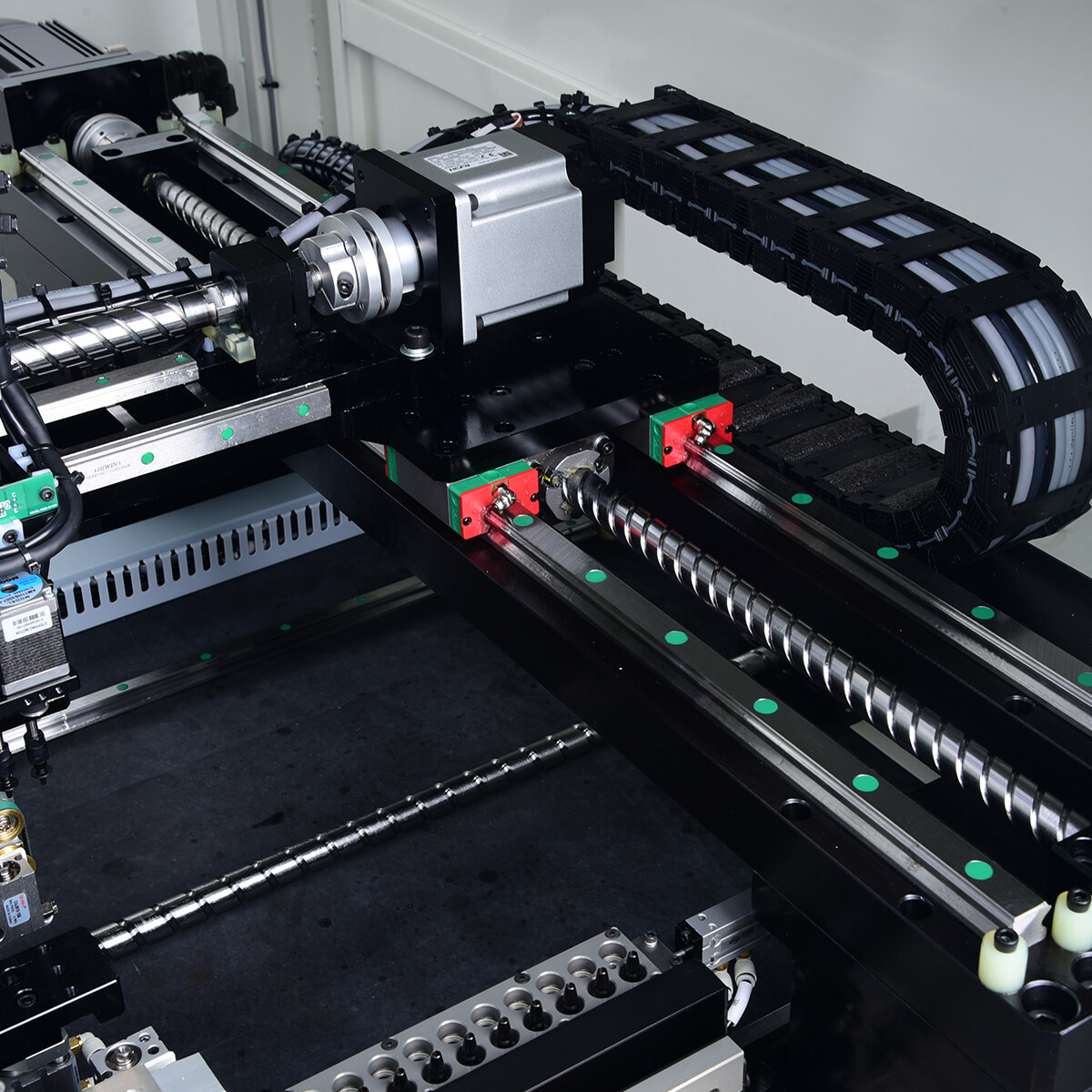

b) Pick-and-Place Machine: Uses automated robotic arms to place SMT components onto the PCB with incredible speed and accuracy.

c) Reflow Oven: Heats the PCB to melt the solder paste, forming strong electrical connections between the components and the board.

d) Inspection Systems: Utilizes automated optical inspection (AOI) and X-ray inspection to detect defects and ensure high-quality production.

2. Advantages of SMT Full Automatic LED Production Line:

a) Increased Productivity: The automation of the LED production process significantly boosts production speed, leading to higher output and reduced manufacturing lead times.

b) Enhanced Precision: Automatic component placement ensures consistent and precise positioning, resulting in improved product quality and reliability.

c) Cost Efficiency: Automated production lines reduce labor costs and minimize the chances of human errors, leading to cost-effective LED manufacturing.

d) Flexibility and Adaptability: Full automatic LED production lines can easily adapt to different LED designs and production volumes, providing manufacturers with the ability to respond swiftly to changing market demands.

3. Chinese Producers' Advantages and Prospects:

a) Technological Advancements: Chinese producers have invested heavily in research and development, leading to the integration of state-of-the-art technology in their SMT full automatic LED production lines. This has allowed them to stay competitive globally.

b) Skilled Workforce: China boasts a large pool of skilled and technically proficient workers, contributing to the efficient operation and maintenance of the production lines.

c) Cost-Effective Manufacturing: The lower labor costs in China offer a significant advantage to domestic LED manufacturers, making their products more price-competitive in the global market.

d) Government Support: The Chinese government has been actively supporting the LED industry, offering incentives and subsidies to encourage technological advancements and promote exports.

e) Expanding Market Share: With an increasing focus on energy-efficient lighting solutions worldwide, the demand for LED products is steadily rising. Chinese producers are well-positioned to capture a significant share of this expanding market.

4. Quality Control and Compliance:

Maintaining high-quality standards is crucial for any industry, and the LED manufacturing sector is no exception. Chinese producers have recognized the importance of adhering to strict quality control measures and international standards. With advancements in inspection systems and automated testing, they can ensure that their LED products meet the required specifications, thus building trust among global consumers and bolstering their reputation as reliable suppliers.

Additionally, Chinese producers are becoming increasingly conscious of environmental regulations and sustainability practices. Implementing eco-friendly manufacturing processes not only aligns with global environmental goals but also appeals to consumers who seek environmentally responsible products.

5. Collaborations and Partnerships:

Chinese LED manufacturers have also been proactive in forming partnerships and collaborations with international companies. By joining forces with established players, they gain access to new markets, technologies, and distribution channels. These collaborations have the potential to foster knowledge exchange and innovation, enabling Chinese producers to further enhance their SMT full automatic LED production lines.

Furthermore, such partnerships can lead to joint research and development efforts, resulting in the creation of cutting-edge products and solutions that cater to the ever-evolving demands of the LED industry.

6. Challenges Ahead:

Despite the remarkable growth and success of the SMT full automatic LED production line in China, challenges remain. One significant challenge is the intense competition within the LED manufacturing sector. As more countries invest in LED technology and automation, Chinese producers face the need to continually innovate and differentiate their offerings to maintain their competitive edge.

Moreover, with automation comes the requirement for skilled labor with technical expertise to operate and maintain these sophisticated production lines. Ensuring a steady supply of skilled workers and providing them with ongoing training and development opportunities will be essential for sustained growth.

Additionally, geopolitical factors, international trade disputes, and shifting market dynamics can influence the LED industry's landscape. Chinese producers must remain adaptable and agile in response to these external factors to navigate potential uncertainties.

7. Conclusion:

China's SMT full automatic LED production line exemplifies the country's dedication to technological advancement and manufacturing excellence. With its robust automation, precise production processes, and commitment to quality control, the Chinese LED industry has garnered recognition and trust from global customers.

While challenges lie ahead, Chinese producers have demonstrated resilience, innovation, and adaptability in overcoming obstacles. With strong government support, skilled labor force, and increasing global demand for LED products, Chinese producers are well-positioned to continue their upward trajectory and shape the future of the LED manufacturing industry on a global scale. As technology evolves and markets expand, China's SMT full automatic LED production line is poised to lead the charge in driving innovation and efficiency within the LED industry.

Overall, the SMT full automatic LED production line is an exemplar of China's manufacturing prowess and a testament to its commitment to meeting the demands of a rapidly evolving global industry. As it advances further, it will continue to redefine the LED manufacturing landscape and maintain its position as a frontrunner in the global LED revolution.

China's SMT full automatic LED production line embodies the pinnacle of manufacturing excellence, leveraging cutting-edge technology and skilled labor to deliver high-quality LED products at competitive prices. With a strong focus on research and development, coupled with government support and a burgeoning global market, Chinese producers are set to continue their ascent in the LED manufacturing industry. As technology advances and market demands evolve, the prospects for China's SMT full automatic LED production line remain promising, cementing its position as a driving force in the global LED revolution.

HCT-530LV Automatic 1.2M LED Pick and Place Machine

The desktop automatic pick and place machine HCT-530LV Automatic 1.2M LED Pick and Place Machine was created with research laboratories and small to medium manufacturing firms in mind, but it may also be used by serious hobbyists. These robotic pick-and-place systems are appropriate for small-batch manufacturing, in-lab product testing, research and development, LED SMT assembly, and other related procedures.

HCT-1200-SV Automatic 8 Heads LED SMD Pick & Place Machine

The PCB pick and place machine is a type of SMT machinery used in the SMT manufacturing line to achieve high-speed and high-precision component placement. The PCB SMT pick and place equipment is typically set up following the dispenser screen printing equipment. By adjusting the mounting head, the surface mount components are attached precisely. The most crucial, intricate, and significant piece of machinery in the entire SMT line is the PCB pad.

HCT-530SV Semi-auto 8 Heads LED SMD Mounter

The pick and place machine is the most precise and complicated piece of SMT equipment since it is the most crucial part of the SMT manufacturing line. The working environment must meet a number of conditions for the pick and place machine. The slider's service life can be increased and its failure rate can be decreased in a positive work environment.