Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

China High Accuracy Pick And Place Machine Manufacturer

Surface-mount technology (SMT) component placement systems, commonly called pick-and-place machines or P&Ps, are robotic machines that are used to place surface-mount devices (SMDs) onto a printed circuit board (PCB). They are used for high speed, high precision placing of a broad range of electronic components, like capacitors, resistors, and integrated circuits onto the PCBs which are in turn used in computers, consumer electronics as well as industrial, medical, automotive, military, and telecommunications equipment. Similar equipment exists for through-hole components.

The High Accuracy Pick and Place Machine is a cutting-edge automated assembly equipment designed for precise and efficient placement of surface mount components onto printed circuit boards (PCBs). This advanced machine plays a pivotal role in modern electronics manufacturing, where high precision, speed, and reliability are essential to meet the demands of increasingly complex and miniaturized electronic devices.

Key Features and Functionality:

-

Precision Component Placement: The High Accuracy Pick and Place Machine employs advanced vision systems, laser alignment, and sophisticated algorithms to achieve ultra-precise component placement. It can handle components with varying shapes, sizes, and orientations, ensuring accurate positioning on the PCB.

-

High-Speed Production: Equipped with multiple robotic arms and high-speed actuators, the machine can rapidly pick up components from tape reels, trays, or sticks and place them with lightning-fast speed onto the PCB, significantly boosting production throughput.

-

Versatility and Flexibility: This pick and place machine is highly versatile and adaptable, capable of handling a wide range of component types, including resistors, capacitors, integrated circuits, LEDs, and more. It can accommodate various PCB sizes and configurations, offering manufacturers the flexibility to cater to diverse product requirements.

-

Efficient Component Feeding: The machine employs advanced feeding mechanisms to optimize the component supply process. It can efficiently handle reels, tubes, trays, and cut tapes, ensuring a steady and uninterrupted material flow during production.

-

User-Friendly Interface: The High Accuracy Pick and Place Machine features an intuitive and user-friendly interface, allowing operators to set up and control the machine effortlessly. It supports quick changeovers between different product assemblies, reducing downtime and increasing overall productivity.

-

Automatic Calibration and Inspection: To maintain accuracy and consistency, the machine incorporates automatic calibration routines to regularly align its vision systems and placement mechanisms. Additionally, integrated inspection systems can detect misplaced or missing components, ensuring a high first-pass yield and minimizing defects.

Applications:

The High Accuracy Pick and Place Machine is widely used in various industries that rely on electronics assembly, including consumer electronics, automotive, telecommunications, medical devices, aerospace, and more. It is particularly suited for applications where precise component placement and high-speed production are critical, such as in miniaturized wearable devices, smartphones, high-density PCBs, and IoT devices.

Benefits:

-

Improved Product Quality: The machine's high accuracy and consistency in component placement lead to better solder joint quality, reduced rework, and improved overall product reliability.

-

Increased Productivity: With its rapid pick-and-place capabilities, the machine significantly reduces cycle times, thereby increasing production output and meeting tight deadlines.

-

Cost Efficiency: By minimizing errors and optimizing material usage, the machine contributes to lower production costs, providing a competitive advantage to manufacturers.

-

Scalability: The machine's adaptability to different PCB sizes and component types allows manufacturers to scale their production and accommodate future product developments.

China has emerged as a major player in the global electronics manufacturing industry, including the production of High Accuracy Pick and Place Machines. Several Chinese manufacturers have gained recognition for their advanced technologies, cost-effectiveness, and commitment to quality. Let's explore some key Chinese High Accuracy Pick and Place Machine manufacturers and their respective advantages:

1. Company A: HCT Electronics Technology Co., Ltd.

Advantages:

- Cutting-Edge Technology: HCT Electronics Technology Co., Ltd. invests heavily in research and development, ensuring their pick and place machines are equipped with the latest advancements in vision systems, precision control, and automated calibration. This commitment to innovation allows them to offer state-of-the-art machines with exceptional accuracy.

- Competitive Pricing: The company leverages China's cost advantages to provide high-quality pick and place machines at competitive prices, making them an attractive choice for both domestic and international customers.

- Wide Product Range: HCT Electronics offers a diverse range of High Accuracy Pick and Place Machines, catering to various PCB sizes, component types, and production volumes. This versatility allows customers to find a suitable solution for their specific assembly needs.

2. Company B: YX Electronics Equipment Co., Ltd.

Advantages:

- Customization Options: YX Electronics Equipment Co., Ltd. excels in offering tailored solutions to meet specific customer requirements. They collaborate closely with clients to understand their production needs and provide customized pick and place machines that optimize production efficiency and accuracy for their unique applications.

- After-Sales Support: The company is renowned for its excellent after-sales service, including technical assistance, spare parts availability, and maintenance support. This level of customer care ensures the smooth and uninterrupted operation of their machines, enhancing customer satisfaction.

- International Certifications: YX Electronics has earned various international certifications, including ISO 9001 and CE, attesting to the company's adherence to high-quality manufacturing standards and compliance with global regulations.

3. Company C: PQR Automation Technology Co., Ltd.

Advantages:

- High Production Capacity: PQR Automation Technology Co., Ltd. possesses advanced manufacturing facilities with a high production capacity, allowing them to fulfill large-scale orders efficiently. Their ability to handle bulk production makes them a preferred choice for customers with substantial manufacturing requirements.

- Robust Quality Control: The company maintains strict quality control measures throughout the production process. Each High Accuracy Pick and Place Machine undergoes rigorous testing to ensure it meets stringent performance and reliability standards before reaching the customer.

- Global Presence and Support: PQR Automation has a strong global presence, with a well-established network of sales and service centers. This enables them to offer timely support and assistance to customers worldwide, regardless of their location.

Conclusion:

Chinese High Accuracy Pick and Place Machine manufacturers have achieved remarkable success in the electronics manufacturing industry, owing to their focus on technological innovation, cost-effective solutions, customer-centric approach, and robust quality control measures. As the demand for precise and efficient electronics assembly continues to grow, these manufacturers are well-positioned to remain competitive and contribute significantly to the advancement of the global electronics manufacturing landscape.

HCT manufactures high-accuracy pick and place machines for PCB assembly at affordable prices. Made in China. Quality Assurance. Contact us now!

HCT-530LV Automatic 1.2M LED Pick and Place Machine

The desktop automatic pick and place machine HCT-530LV Automatic 1.2M LED Pick and Place Machine was created with research laboratories and small to medium manufacturing firms in mind, but it may also be used by serious hobbyists. These robotic pick-and-place systems are appropriate for small-batch manufacturing, in-lab product testing, research and development, LED SMT assembly, and other related procedures.

HCT-1200-SV Automatic 8 Heads LED SMD Pick & Place Machine

The PCB pick and place machine is a type of SMT machinery used in the SMT manufacturing line to achieve high-speed and high-precision component placement. The PCB SMT pick and place equipment is typically set up following the dispenser screen printing equipment. By adjusting the mounting head, the surface mount components are attached precisely. The most crucial, intricate, and significant piece of machinery in the entire SMT line is the PCB pad.

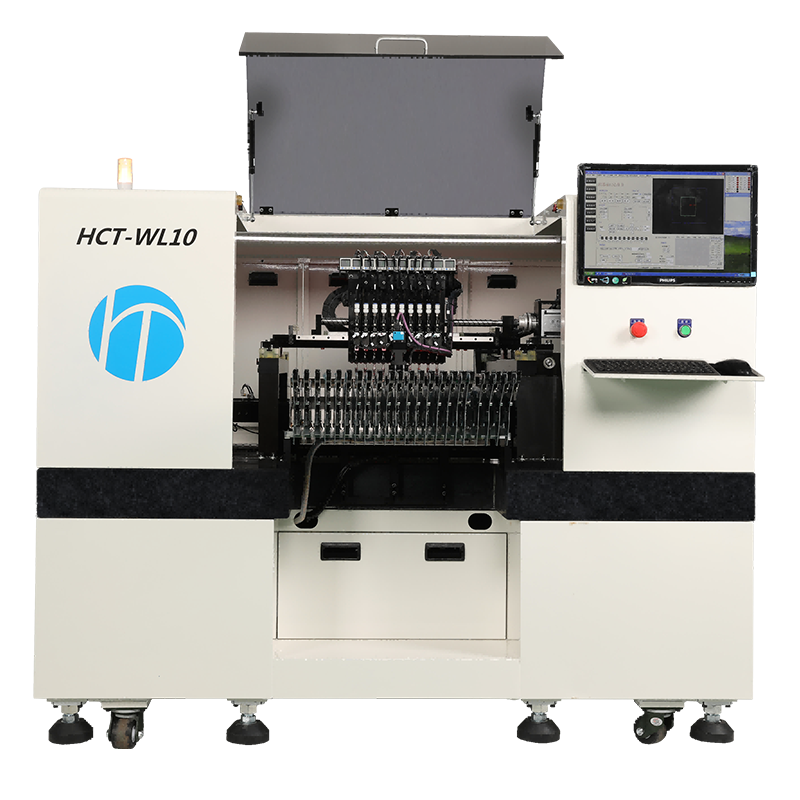

HCT-WL10 Automatic Copper Wire Lamp Placement Machine

Different working files are loaded onto the SMT pick and place machine in order to attach the corresponding PCB. Please get in touch with us if you have any questions concerning the cost of a PCB pick and place machine, PCB soldering machine, PCB component placement machine, or PCB SMT assembly machine.

HCT-830L High-speed LED Chip Mounter

With the development of science and technology, electronic items are a part of everyone's life. To fulfill its purpose, every electrical product needs a PCB as a carrier. Some PCBs contain hundreds of components, and manual soldering of PCBs has long fallen short of market demands. The PCB component placement machine is the most crucial piece of the PCB assembly chain, and the simplest SMT line typically comprises a solder printer, a pick and place device, and a reflow oven.

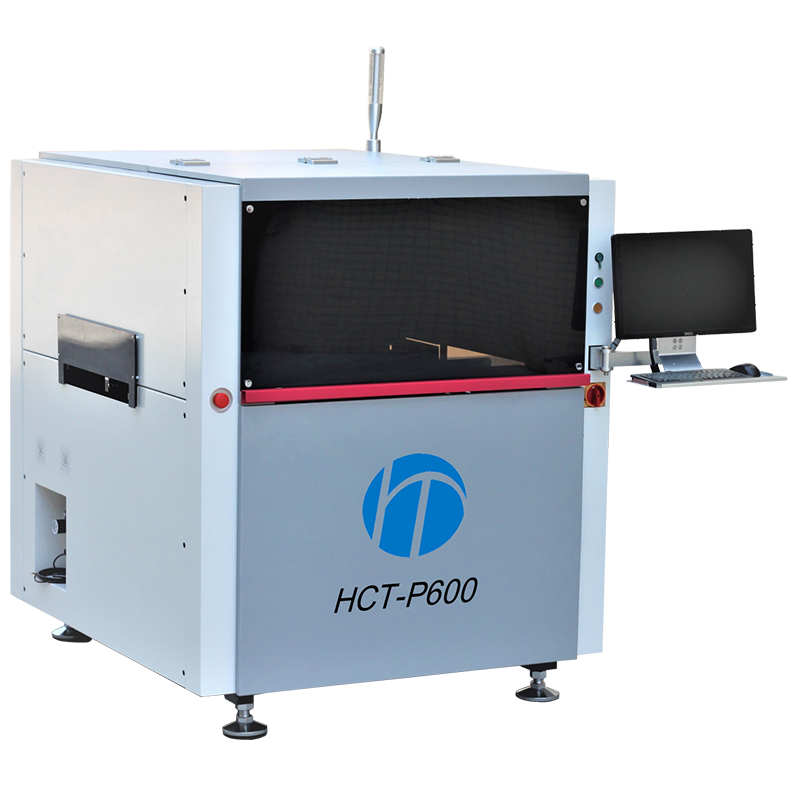

High Accuracy Automatic Solder Paste Stencil Printer

The system offers three different cleaning techniques—dry cleaning, wet cleaning, and vacuum—that can be combined in any way and support manual cleaning in the production interface, cutting down on cleaning time and boosting production effectiveness.