Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

China Pick And Place SMT Machine

With the development of industrialization, the pick and place machine is one of the necessary automated machines in the electronics manufacturing industry.

A SMT electronics pick and place machine is a robotic assembly device that uses a vacuum to lift a component off a piece of tape, rotates it to the right orientation, then places it on a circuit board, which is also called the circuit board pick and place machine, namely, PCB assembly machine/equipment. It takes a few hours to set up a surface mount pick and place machine to build the assembly, but once everything is running, it works very fast.

HCT is a professional SMT placement machine manufacturer integrating R&D, production, and sales. We have a professional after-sales team to provide 24-hour online after-sales consultation and problem handling.

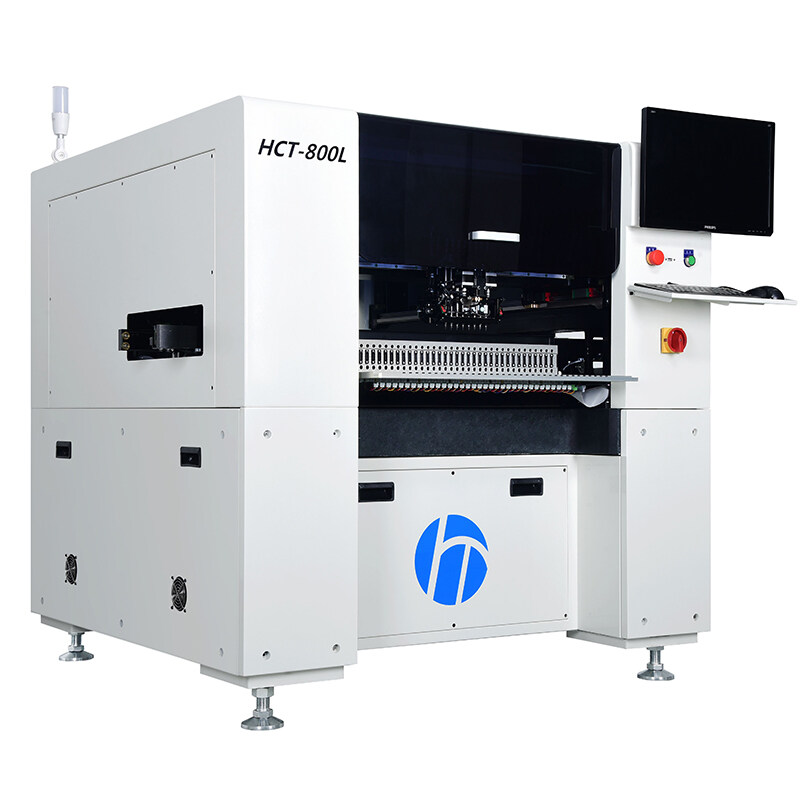

HCT-800L Multifunctional SMT Pick and Place Machine

Along with dust, there might also be various chemical fumes present in the production environment of the SMT pick and place machine. The reliability of the product will be significantly impacted if these gases are corrosive or include any dangerous compounds that could harm humans or animals. As a result, the workplace needs to be kept dust-free, corrosive, and gas-free. This guarantees the product's weld quality, the equipment's smooth operation, and the operators' wellbeing.

HCT-1200-SV Automatic 8 Heads LED SMD Pick & Place Machine

The PCB pick and place machine is a type of SMT machinery used in the SMT manufacturing line to achieve high-speed and high-precision component placement. The PCB SMT pick and place equipment is typically set up following the dispenser screen printing equipment. By adjusting the mounting head, the surface mount components are attached precisely. The most crucial, intricate, and significant piece of machinery in the entire SMT line is the PCB pad.

HCT-610LV Automatic 10 Heads DOB Pick and Place Machine

Highest LED DOB high component applicability of high-speed chip mounters. All LED lighting products, including flexible PCB strips, circular LED light bulb boards, and even boards with asymmetrical shapes, are suitable for this technology. LED PCBs up to 600mm long can be assembled in a single pass.