Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

pick and place machine manufacturers China

A pick and place machine, also known as a "pick and place robot" or "surface mount placement machine," is a specialized robotic system used in electronics manufacturing to automatically pick up electronic components from a supply source and accurately place them onto a circuit board or other electronic assemblies.

The primary purpose of a pick and place machine is to automate the process of placing surface mount devices (SMDs) onto printed circuit boards (PCBs) during the assembly process. Surface mount technology (SMT) is widely used in modern electronics manufacturing due to its compact size, high-density packaging, and improved electrical performance.

Key features and functionalities of a pick and place machine include:

-

Component Recognition: Pick and place machines are equipped with vision systems comprising cameras and sensors that can recognize and accurately locate components on the feeders or trays.

-

Component Feeders: Electronic components, such as resistors, capacitors, integrated circuits (ICs), and LEDs, are loaded into feeders or trays attached to the pick and place machine. These feeders supply components during the assembly process.

-

Robotic Arm: The core mechanism of the pick and place machine is a robotic arm, which is responsible for picking up components from the feeders and placing them onto the target positions on the PCB.

-

Nozzles and Vacuum System: The robotic arm is equipped with specialized nozzles and a vacuum system to pick up and hold components securely during the placement process.

-

Accuracy and Speed: Pick and place machines are designed to achieve high placement accuracy and speed, enabling fast and precise component placement.

-

Component Orientation: The machine can handle components with different orientations, allowing them to be placed in the correct alignment on the PCB.

-

Programming Interface: Operators use a programming interface or software to input the design files and specify the exact locations and orientations where the components need to be placed on the PCB.

-

Automatic Calibration: Some advanced pick and place machines have automatic calibration features to ensure precise and repeatable component placement.

-

Vision-Based Inspection: Some machines may have inspection capabilities to verify the placement accuracy and detect any defects.

Pick and place machines are essential in electronics manufacturing for various products, including:

-

Consumer Electronics: Such as smartphones, tablets, laptops, cameras, and gaming consoles.

-

Automotive Electronics: For components used in vehicles, such as engine control units (ECUs), infotainment systems, and sensors.

-

Industrial Electronics: Used in industrial automation, control systems, and communication equipment.

-

Medical Devices: For assembling medical devices like monitoring equipment, diagnostic devices, and implantable devices.

-

LED Lighting: For assembling LED drivers, LED strips, and other lighting products.

The automation provided by pick and place machines significantly improves production efficiency, reduces manual labor, and enhances the overall quality and reliability of electronic products.

Pick And Place Machine Manufacturers China

As of my last update in September 2021, China is home to several prominent pick and place machine manufacturers. Please note that the manufacturing landscape may have changed since then, and new companies may have emerged. Here are some well-known pick and place machine manufacturers in China:

-

Hanwha Techwin (former Samsung Techwin): Hanwha Techwin is a South Korean company with a significant presence in China, offering a range of SMT equipment, including pick and place machines.

-

Juki Corporation: Juki is a Japanese company with manufacturing operations in China. They are a leading supplier of SMT placement machines.

-

Shenzhen ETON Automation Equipment Co., Ltd.: ETON is a Chinese company specializing in the research, development, and manufacturing of pick and place machines. They offer a variety of models to meet different production needs.

-

Shenzhen JT Automation Equipment Co., Ltd.: JT Automation is a Chinese manufacturer of SMT equipment, including pick and place machines. They provide solutions for various industries, including electronics, automotive, and telecommunications.

-

Beijing Torch Co., Ltd.: Beijing Torch is a well-known Chinese company that manufactures SMT equipment, including pick and place machines, soldering machines, and screen printers.

-

Hangzhou NeoDen Technology Co., Ltd.: NeoDen is a Chinese company focused on the research, development, and production of desktop pick and place machines for small and medium-sized production requirements.

-

Changsha Chuanke Intelligent Machinery Co., Ltd.: Chuanke is a Chinese manufacturer specializing in the production of pick and place machines, dispensing machines, and other SMT equipment.

- When considering any manufacturer for purchasing SMT equipment, including pick and place machines, it's essential to conduct thorough research, read customer reviews and testimonials, and, if possible, visit their facilities or attend industry exhibitions to see the machines in action. Additionally, verifying the company's reputation, customer support, and after-sales service is crucial to ensure a smooth and successful purchasing experience.

HCT-610LV Automatic 10 Heads DOB Pick and Place Machine

Highest LED DOB high component applicability of high-speed chip mounters. All LED lighting products, including flexible PCB strips, circular LED light bulb boards, and even boards with asymmetrical shapes, are suitable for this technology. LED PCBs up to 600mm long can be assembled in a single pass.

HCT-530LV Automatic 1.2M LED Pick and Place Machine

The desktop automatic pick and place machine HCT-530LV Automatic 1.2M LED Pick and Place Machine was created with research laboratories and small to medium manufacturing firms in mind, but it may also be used by serious hobbyists. These robotic pick-and-place systems are appropriate for small-batch manufacturing, in-lab product testing, research and development, LED SMT assembly, and other related procedures.

HCT-T100 Small 4 Heads SMD Pick and Place Machine

The major benefit of employing SMT machines for LED manufacturing is that hand assembly variations are completely eliminated. Multiple components are placed on the board simultaneously by the accurate and very accurate automatic led pick and place system, greatly increasing production and lowering labor costs. As human participation has been reduced, the efficiency of SMT-based LED component manufacturing has grown tremendously.

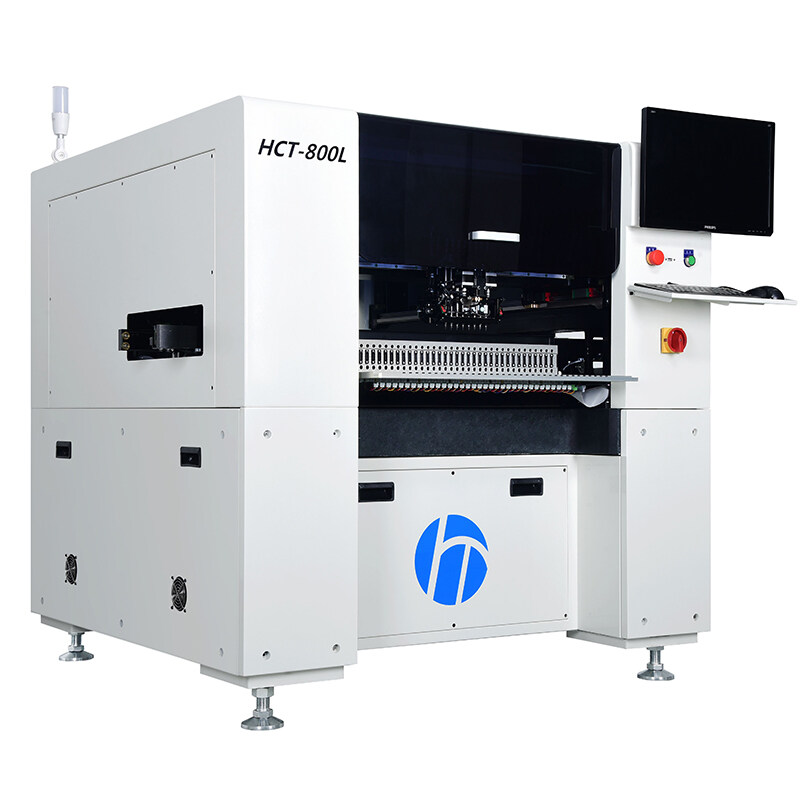

HCT-800L Multifunctional SMT Pick and Place Machine

Along with dust, there might also be various chemical fumes present in the production environment of the SMT pick and place machine. The reliability of the product will be significantly impacted if these gases are corrosive or include any dangerous compounds that could harm humans or animals. As a result, the workplace needs to be kept dust-free, corrosive, and gas-free. This guarantees the product's weld quality, the equipment's smooth operation, and the operators' wellbeing.