Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

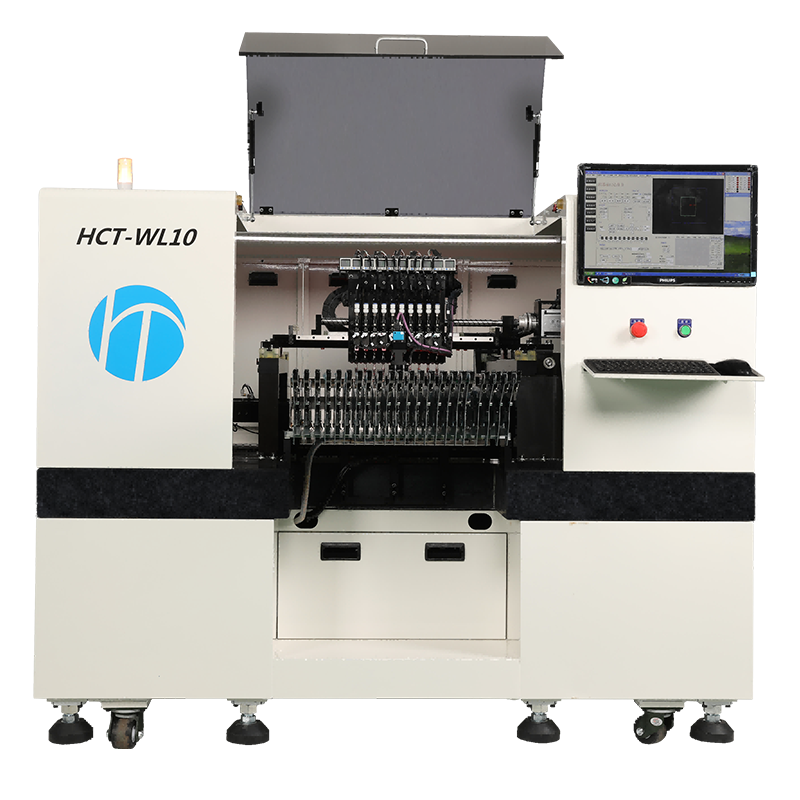

HCT-810L Automatic 10 Heads DOB Pick and Place Machine

The HCT-810L is a cutting-edge placement machine equipped with the advanced Flying Vision Alignment System. With its bottom fixed cameras and 10 spindles on a single gantry, this machine offers exceptional precision and speed in component placement.

The HCT-810L stands at the forefront of placement machine technology, boasting the revolutionary Flying Vision Alignment System. This state-of-the-art system, combined with its bottom fixed cameras and 10 spindles on a single gantry, elevates the machine’s capabilities to unparalleled levels of precision and speed in component placement.

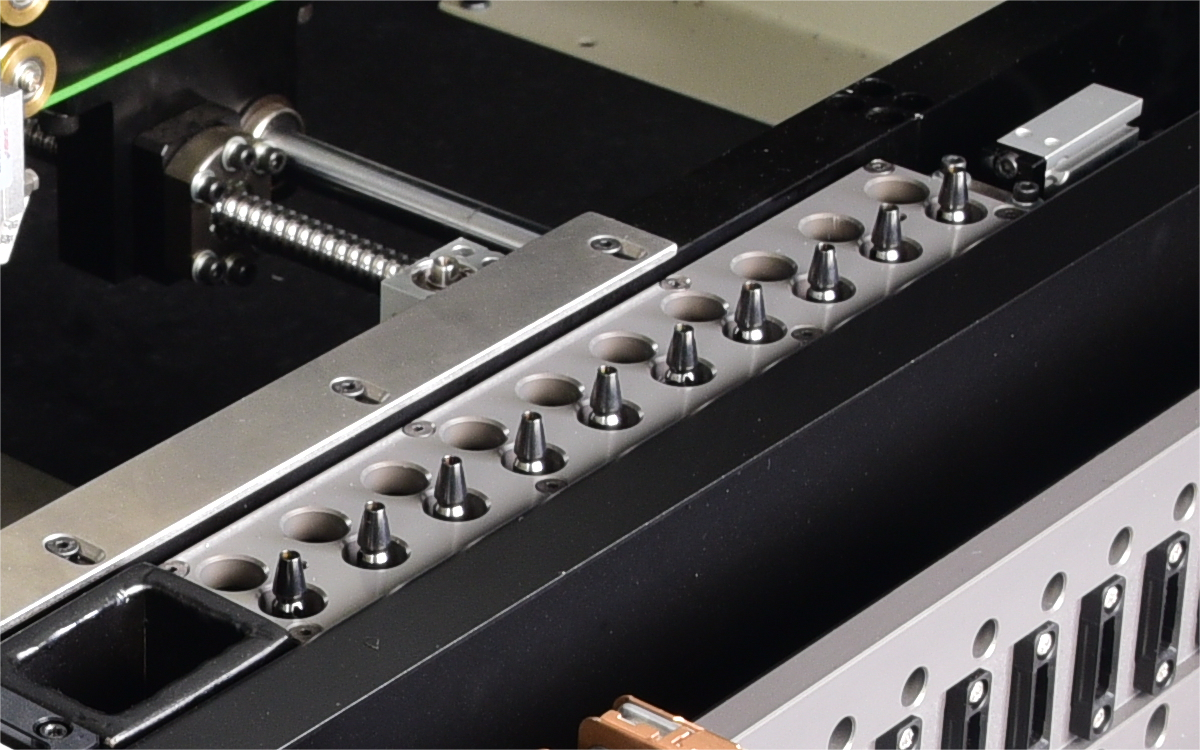

P&P Machine Standard Spare Parts List:

No. Specifications Qty

1. Nozzles *30

2 .Hexagon Wrench Tool * 1

3 .Material Rack * 1

Product Features

- Automatic Nozzle Calibration: The machine is equipped with automatic nozzle calibration functionality, ensuring precise and accurate component placement without the need for manual adjustments.

- Intelligent Component Recognition: The HCT-810LV utilizes advanced image processing technology to automatically recognize and identify different components, reducing setup time and minimizing errors.

- Multi-functional Placement Heads: Each of the 10 placement heads is capable of handling various component types and sizes, providing versatility and flexibility in production.

- User-friendly Interface: The machine features a user-friendly interface with intuitive controls, making it easy for operators to set up and operate the machine efficiently.

- High-speed Vision Alignment: The flying vision alignment system enables fast and accurate component alignment, resulting in high-speed placement and increased productivity.

Specification

|

Model |

HCT-810L |

|

|

Alignment |

Flying Vision Alignment System (Bottom Fixed Cameras) |

|

|

Number of Spindles |

10 Spindles x 1 Gantry |

|

|

RatedPlacement Speed |

Vision Alignment |

30,000 CPH (Optimum) |

|

Placement Accuracy |

±0.05mm (Based on the standard chips) |

|

|

Mechanical Precision |

±0.02mm |

|

|

Component Range |

Fly Camera |

0402(inch)~20x20(mm) |

|

Max Height |

H=20mm |

|

|

Board Dimension(mm) |

Minimum |

50(L) x 50(W) |

|

Maximum |

400(L) x350(W) |

|

|

PCB Thickness |

0.5 - 3.0 |

|

|

Board Handling Method |

Inline Conveyor (3-section Transmit ) |

|

|

Tape Feeder |

Feeder Type |

ElectricFeeder |

|

Feeder Capacity |

35 (16mm Standard) |

|

|

Optional |

8mm, 12mm, 16mm, 24mm, 32mm |

|

|

Utility |

Power |

AC 220V/240V 50/60Hz, Single phase |

|

Max3.0KW |

||

|

AirSupply |

Built-in Vacuum Pump (for nozzles only) |

|

|

Mass |

Approx.1600kg |

|

|

External Dimension(mm) |

1,780(L) x1,700(D) x 1,500(H) |

|

Product Advantages

1.Improved Placement Accuracy: With a placement accuracy of ±0.05mm, the machine ensures precise and reliable placement of components, reducing the risk of defects and improving overall product quality.

2.Efficient Material Management: The machine is equipped with a material rack and a comprehensive inventory management system, allowing for efficient handling and tracking of components during production.

3.Remote Monitoring and Control: The HCT-810LV supports remote monitoring and control capabilities, enabling operators to monitor production status and make adjustments remotely, improving operational efficiency.

4.Excellent Hardware Support: The machine is built with high-quality hardware components from renowned brands, ensuring long-term reliability, stability, and durability.

Product Display