Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

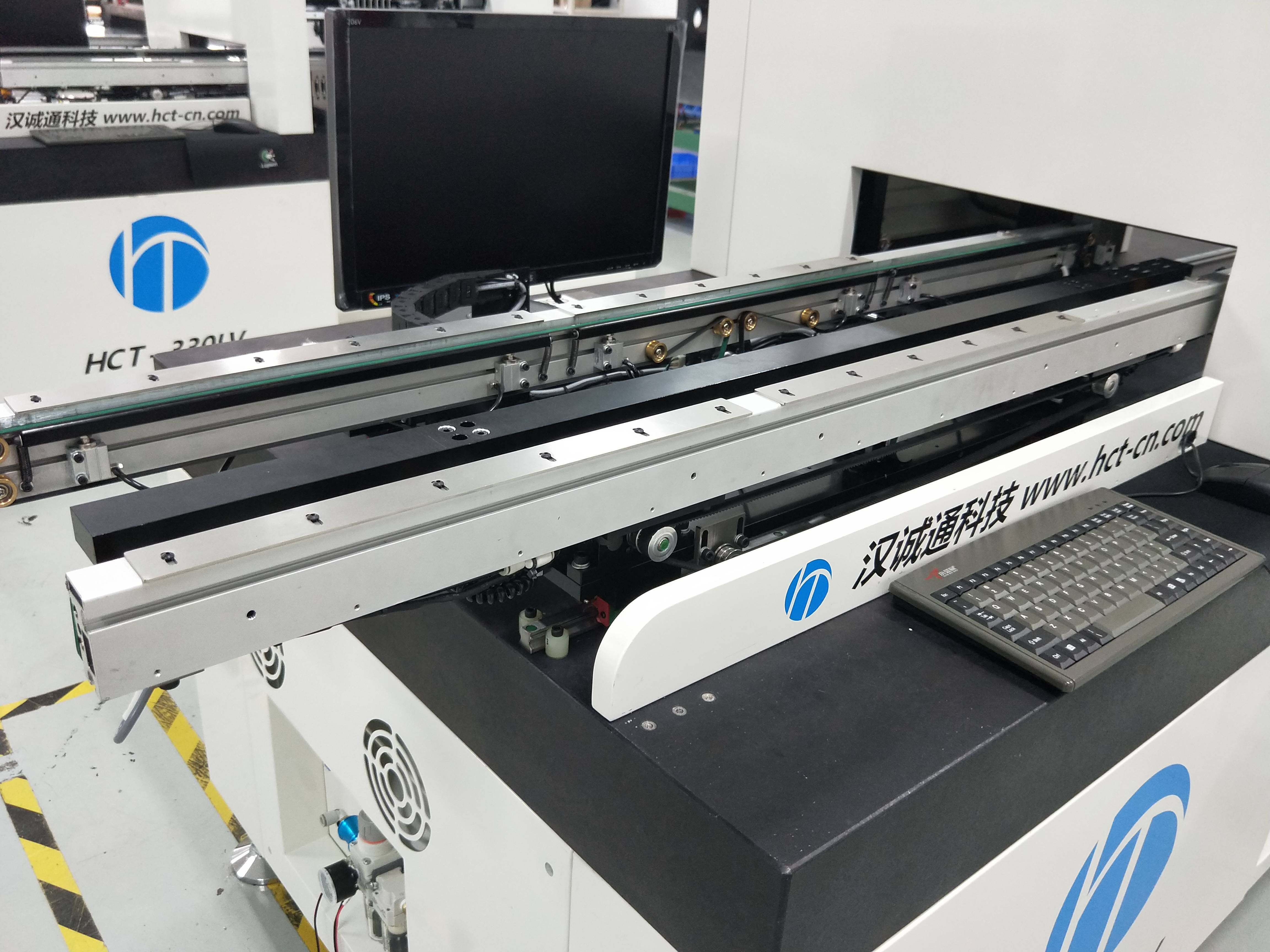

HCT-330LV Automatic 6 Heads LED SMT Machine

A precise industrial PCB pick-and-place robot, the SMT pick-and-place machine combines machine-electric-optical, computer control, and automation technology. Through features like suction-displacement-positioning-placement, it quickly and correctly positions SMC/SMD components on the designated pad position on the PCB board without causing any harm to the parts or printed circuit boards.

Technical Parameters - Automatic 6 Heads LED SMT Machine

|

Model |

HCT-330LV |

|

|

Alignment |

Flying Vision Alignment System (Bottom Fixed Cameras) |

|

|

Number of Spindles |

6 Spindles x 1 Gantry |

|

|

RatedPlacementSpeed |

Vision Alignment |

LED 2835 35,000 CPH (Optimum) |

|

Placement Accuracy |

±0.05mm (Based on the standard chips) |

|

|

Component Range |

VisionAlignment |

0603(inch)~5050~7474(mm), high-power LED,IC<10mm |

|

Max Height |

H=10mm (can handle max. 16mm without vision alignment) |

|

|

Board Dimension(mm) |

Maximum |

1,200(L) x 350(W) |

|

Board Handling Method |

Inline Conveyor |

|

|

Tape Feeder |

Feeder Type |

Electric Feeder |

|

Feeder Capacity |

20 (12mm) |

|

|

Optional |

8mm, 12mm, 16mm, 24mm |

|

|

Utility |

Power |

AC 220V/240V 50/60Hz, Single phase |

|

Max2.5KW |

||

|

AirSupply |

0.55-0.7MPa (5.6-7.1kgf/cm2) Built-inVacuum Pump for Nozzles |

|

|

Mass |

Approx.1370kg |

|

|

External Dimension(mm) |

2,000(L) x1,140(D) x 1,350(H) |

|

Product Features - Automatic 6 Heads LED SMT Machine

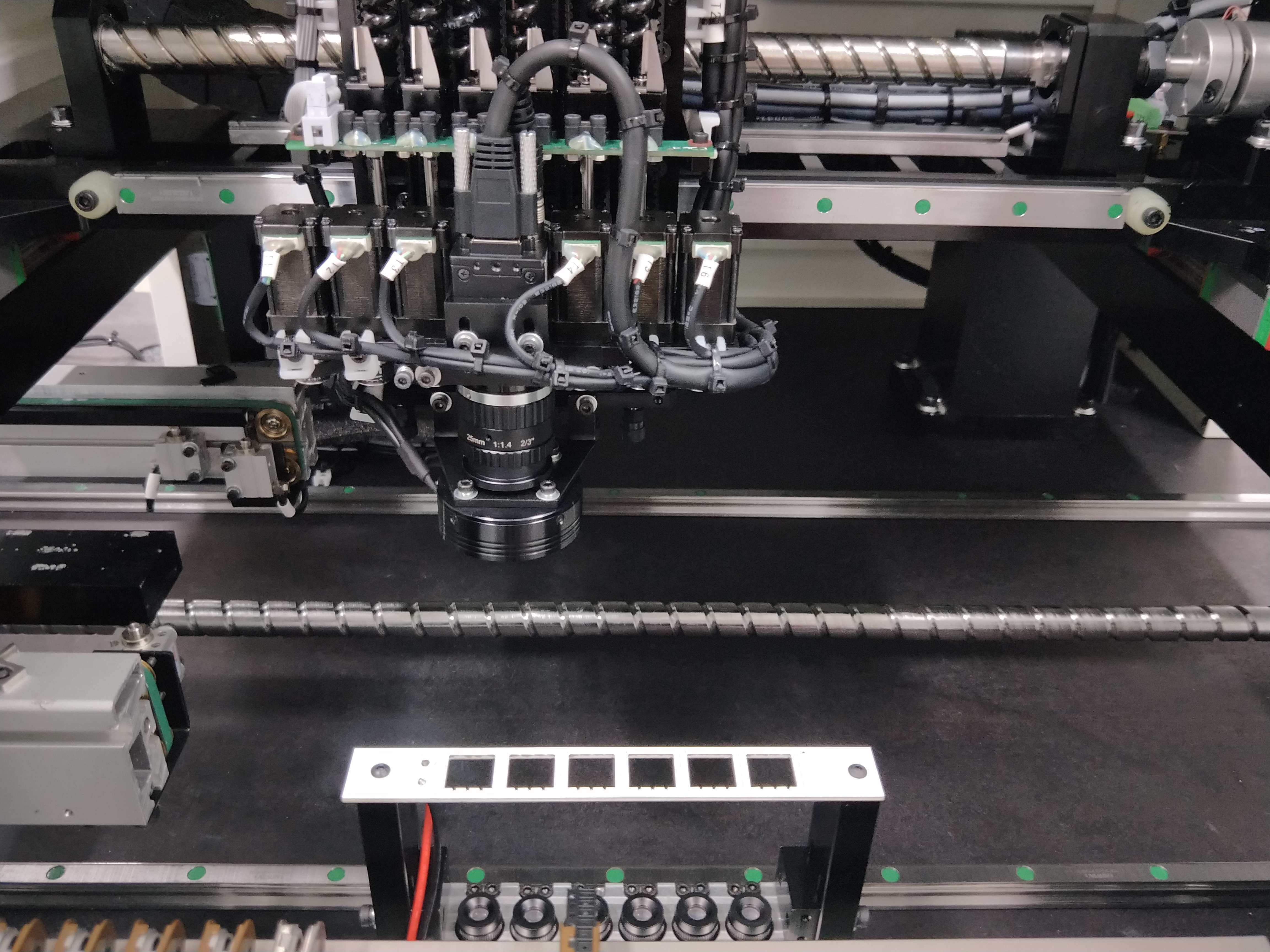

1. High accuracy: Each of the six pick-up heads is equipped with a FLYING vision alignment camera to guarantee high accuracy.

2. High-speed: Maximum placement speed reaching 0.1s/chip.

With a SMEMA-compatible inline conveyor for line automation.

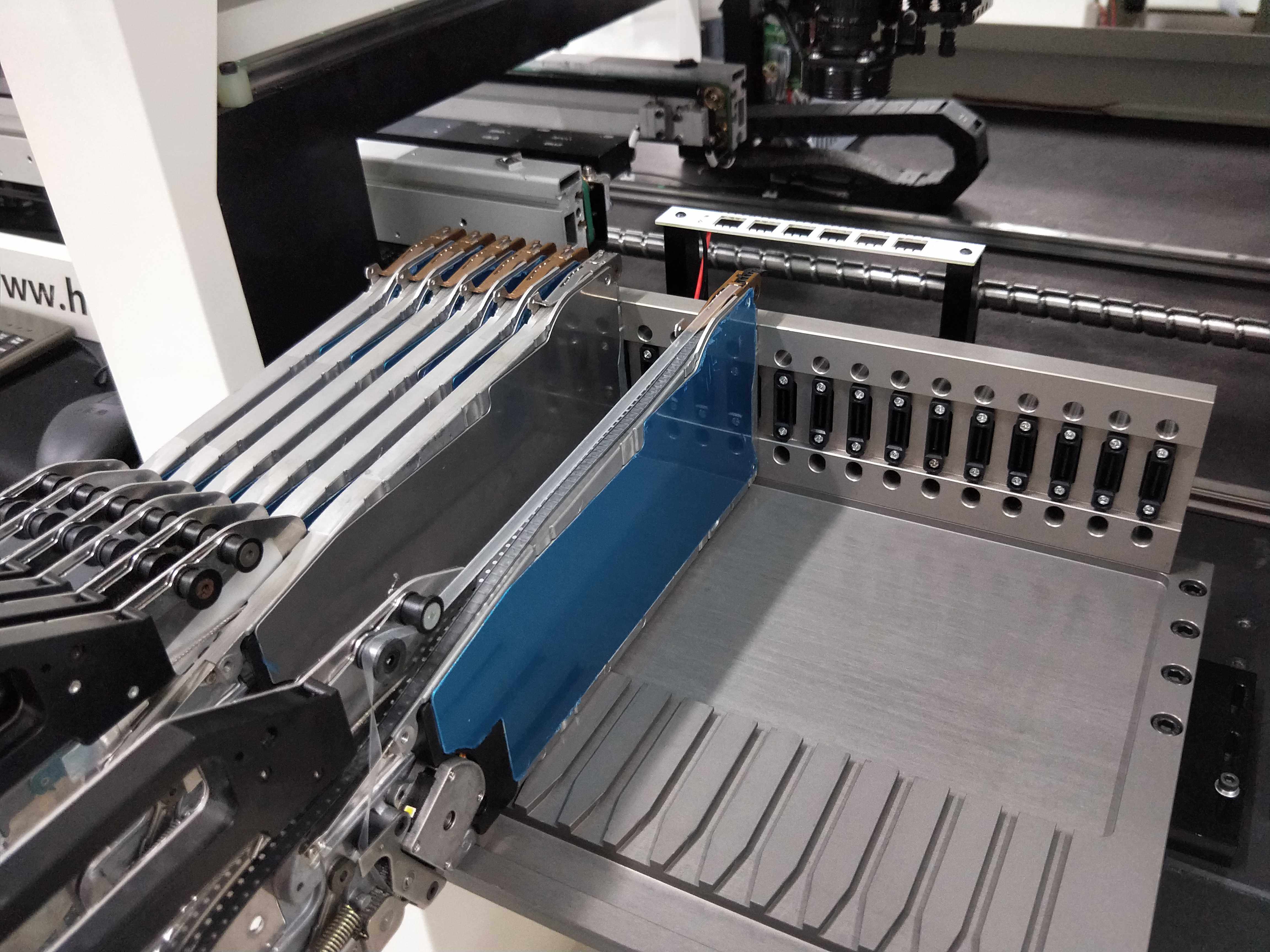

3. Places SMD components from 0603 to 7474, including resistors, capacitors, and standard and irregularly shaped LEDs.

4. Suitable for all LED lighting products assemble LED PCBs up to 1.5 meters long in a single pass.

5. Using motorized feeders for stable and long-life feeding.

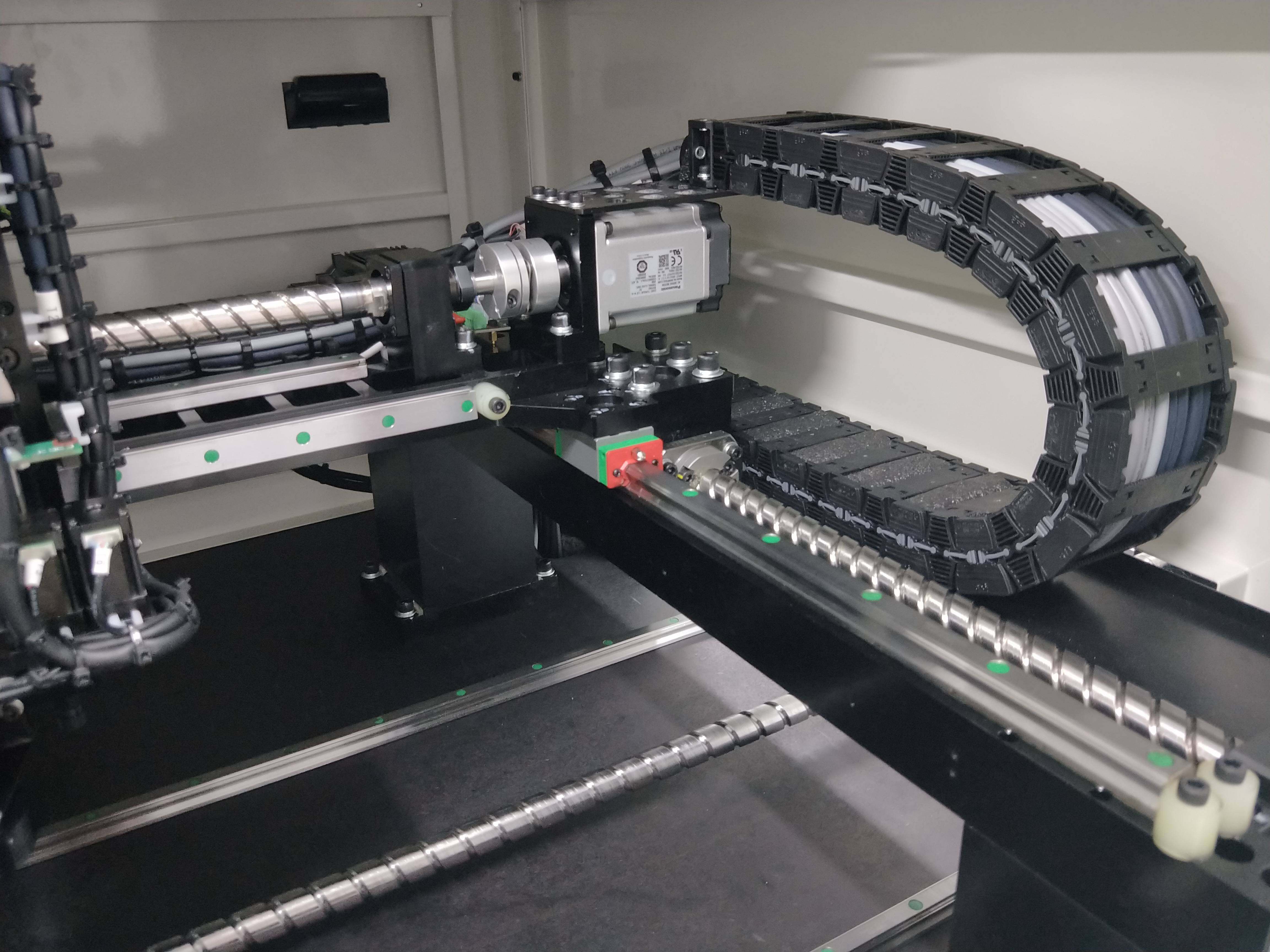

6. Heavy marble platform support to ensure long service life.

7. Excellent quality hardware support by using international famous brands ensures placement repeatability and precision.

8. Self-developed software simplifies production, easy to operate, and programming.

How Does The Pick And Place Equipment Work?

The SMT pick and place machine is a precise industrial PCB pick and place robot, which is a combination of machine-electric-optical and computer control technology. It fastly and accurately places SMC/SMD components on the specified pad position on the PCB board without damaging the components and printed circuit boards through functions such as suction-displacement-positioning-placement. There are three ways of component alignment: mechanical alignment, laser alignment, and visual alignment. The SMT electronics pick and place machine is composed of a rack, an x-y motion mechanism (ball screw, linear guide, drive motor), a placement head, a component feeder, a PCB carrying mechanism, a device alignment detection device, and a computer control system. The movement is mainly realized by the x-y motion mechanism, the power is transmitted through the ball screw, and the directional movement is realized by the rolling linear guide motion pair. The placement position accuracy of each component is guaranteed in this way.

Product Display - Automatic 6 Heads LED SMT Machine