Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

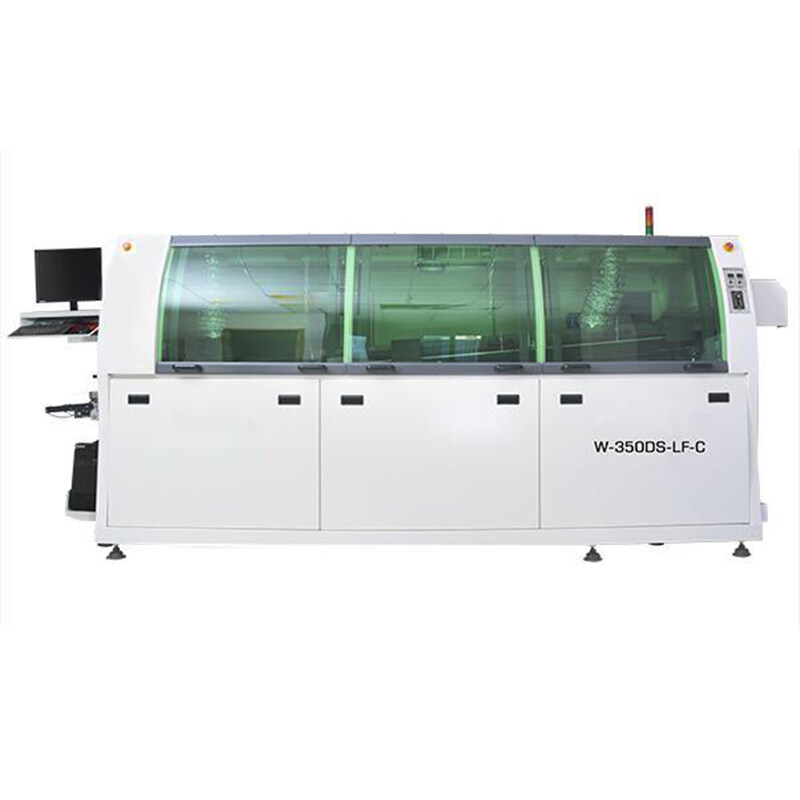

Lead-Free Double-Wave Computer-Controlled Soldering System

Internally modular and with a streamline architecture, it can solder SMT and DIP components without using lead. In order to stop the soldering flux from dripping onto the PCB, the spraying system uses a centrifugal fan to collect air. Sensor for the soldering flux buffer tank is external, more dependable, and robust.

TECHNICAL PARAMETER - Lead-Free Double-Wave Soldering Machine

|

Model No. |

W-350DS-LF-C |

|

Transportation System |

|

|

PCB Width |

Max.350mm |

|

PCBConveyorHeight |

750±20mm |

|

PCBConveyorSpeed |

0-1.8m/min |

|

PCBConveyorDirection |

L→R(R→L option) |

|

Spraying System |

|

|

Spraying Way |

Stepper Motor & ST-6 nozzle |

|

Flux storage tank |

Max.5.2L |

|

Preheating System |

|

|

PreheatingLength |

1800mm |

|

PreheatingZone |

3 zones of hot air, independent control |

|

Preheating Temperatures |

Max. 220℃ |

|

Preheating Power |

10KW |

|

Soldering System |

|

|

ApplicableSolderType |

Lead-free |

|

Melting Tin Quantity |

350KG |

|

WaveSolderingFurnacePower |

16KW |

|

General Parameters |

|

|

Power Supply |

3 Phase 380V(220V option) |

|

AirSupply |

4-7kg/cm2 12.5L/min |

|

Start Power |

25KW |

|

Working Power |

MAX 8KW |

|

TemperatureControl |

Computer Controlled |

|

Control Mode |

Mitsubishi PLC |

|

Weight |

Max 2200kg |

|

Body Dimensions |

L3800xW1350xH1650 MM |

|

Total Dimensions |

L4600xW1350xH1650 MM |

PRODUCT SPECIFICATION - Lead-Free Double-Wave Soldering Machine

- Streamline design and internal modular design, suitable for lead-free soldering of SMT and DIP components.

- The spraying system uses a centrifugal fan to extract air to prevent the soldering flux from dripping onto the PCB.

- Soldering flux buffer tank sensor is external, more reliable, and durable.

- Standard cold air knife to prevent soldering flux mist from spreading out and reduce pollution.

- Dual wave control uses step-less frequency conversion technology, which can independently control the wave height.

- 1 / 4HP high power wave motor, the maximum wave height can reach 15mm.

- With over-temperature sound and light alarm and emergency braking system, all motors have overload protection.

- The transportation system adopts step-less electronic adjustment and closed-loop control, and the speed is stable and accurate.

- The inlet end is equipped with a pressure assist device to prevent the PCB from slipping when entering.

- The track angle is manually adjusted for easy operation.

- The auxiliary nozzle is driven by a stepping motor to ensure uniform coating of the soldering flux.

- In the modular design of the spray system, the spray head is always vertical track, to ensure that the flux penetrates the PCB well.

- The preheating zone is heated by three sections of motors with full hot air, the high temperature throughout, glass protection, and stable temperature.

- The preheating system adopts PID control, and the temperature curve is stable, which can easily find the best settings for various lead-free processes.

China Lead-Free Wave Soldering Machine Manufacturer - HCT

HCT is a reputable manufacturer in China that specializes in lead-free wave soldering machines. They are known for their high-quality equipment used in the electronics manufacturing industry. HCT's lead-free wave soldering machines are designed to meet the stringent requirements of environmentally friendly and RoHS-compliant soldering processes.

Their wave soldering machines offer a range of features to ensure reliable and efficient soldering of printed circuit boards (PCBs). These features may include precise temperature control, adjustable conveyor speed, nitrogen inerting capabilities, automatic fluxing systems, and more. HCT focuses on developing advanced technology to improve soldering quality and maximize production throughput.

As a prominent manufacturer, HCT places importance on customer satisfaction and provides comprehensive technical support. They work closely with their customers to understand their specific needs and offer tailored solutions accordingly.

Before making a final decision, it is recommended to review HCT's product specifications, customer feedback, and warranty terms. Furthermore, contacting HCT directly or reaching out to their authorized distributors can provide additional information and assistance in evaluating their lead-free wave soldering machines for your specific requirements.