Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Precision in Production: A Guide for High-Tech Buyers

Introduction

In the rapidly evolving landscape of high-tech industries, precision in production has become a paramount factor for success. Whether you're involved in electronics, aerospace, medical devices, or any other advanced technology sector, the quality and accuracy of your components can make or break your product. This guide aims to provide high-tech buyers with valuable insights into achieving precision in production, covering essential aspects from selecting suppliers to implementing quality control measures.

1. Supplier Selection

The foundation of precision in production lies in the selection of reliable and skilled suppliers. High-tech buyers must meticulously assess potential suppliers based on their track record, capabilities, and quality management systems. Look for suppliers who specialize in high-precision manufacturing and have a proven history of delivering consistent, high-quality products.

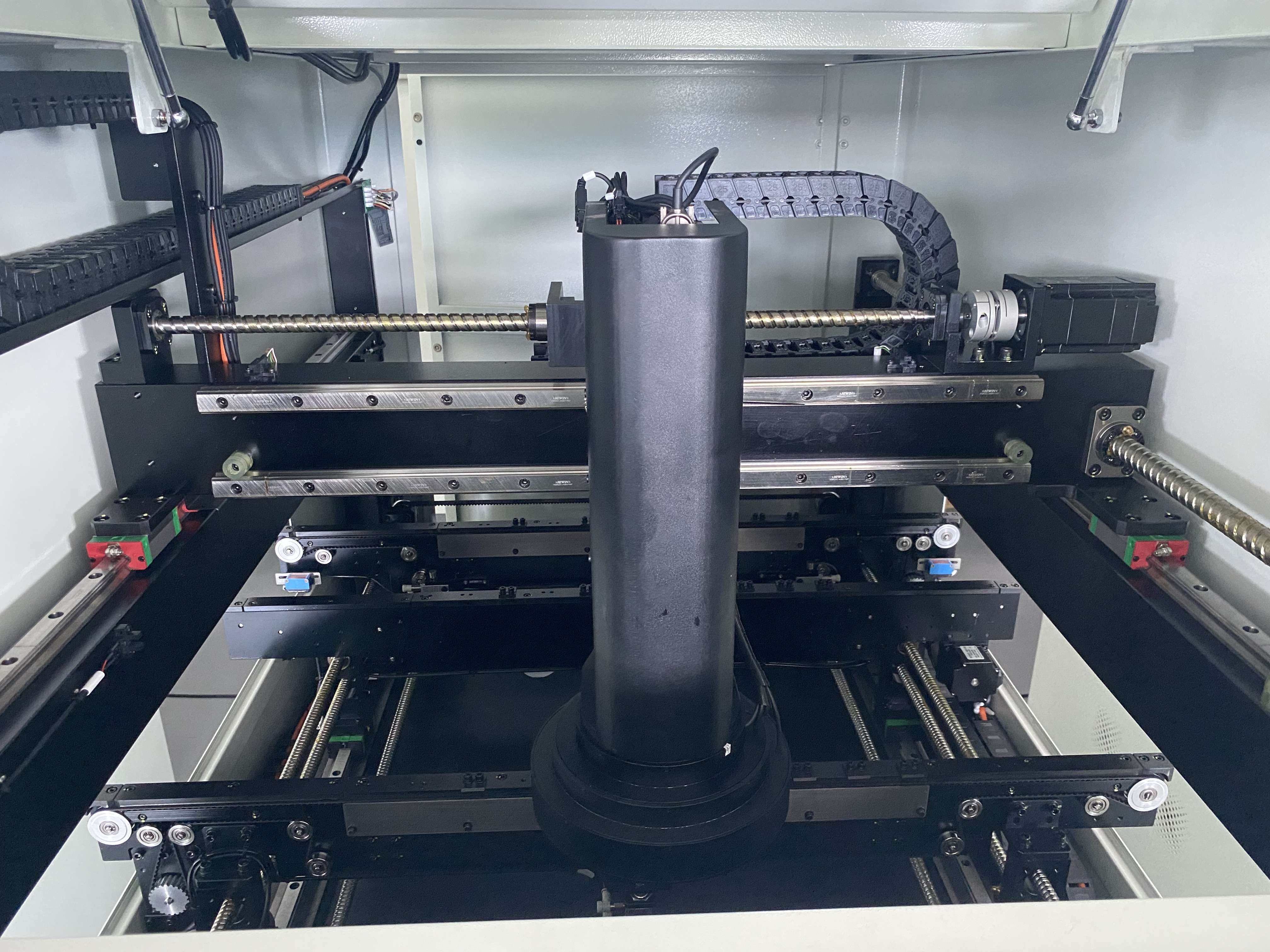

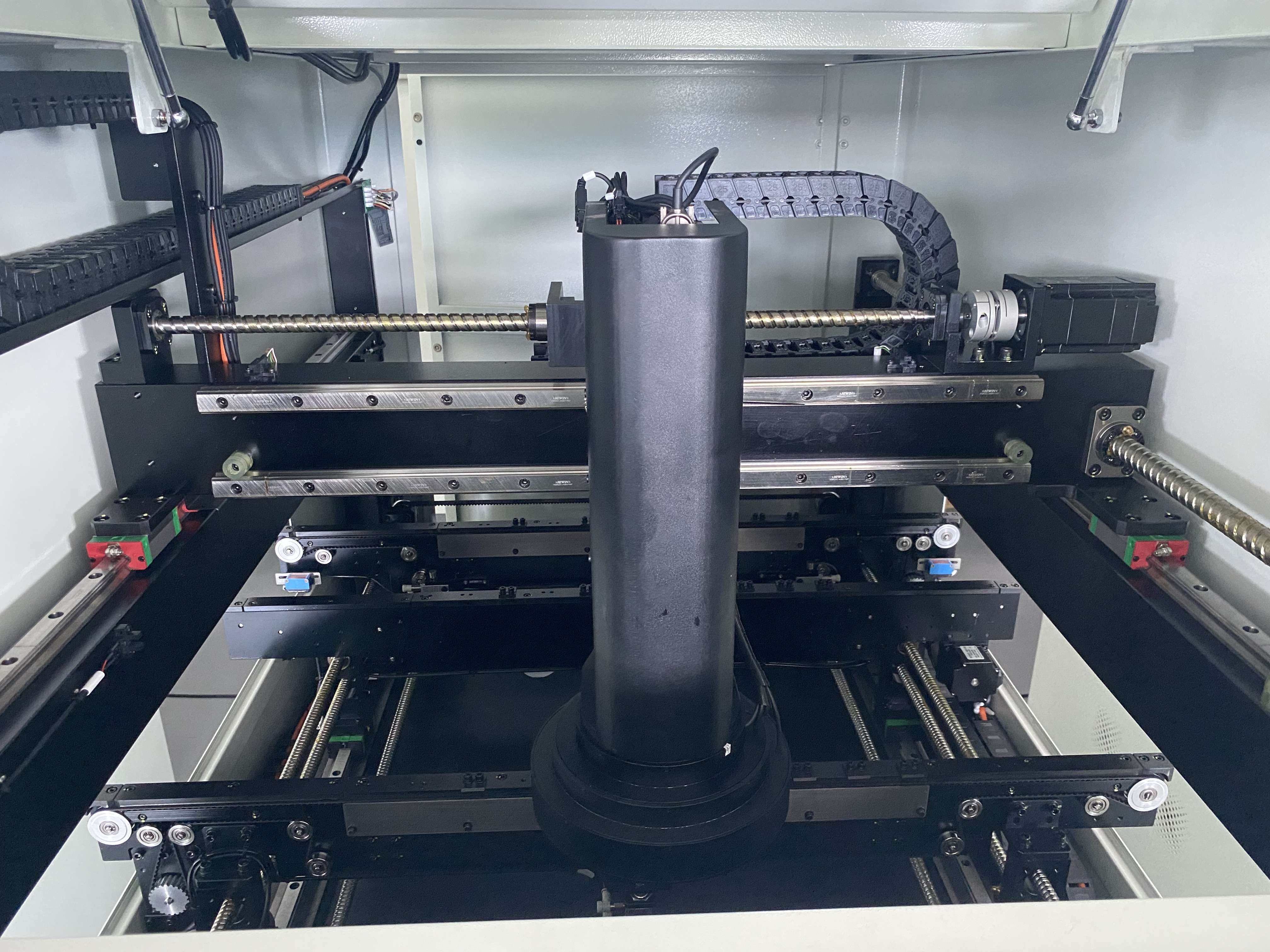

2. Technology Integration

Staying at the forefront of technological advancements is crucial for achieving precision in production. Collaborate with suppliers who leverage cutting-edge technologies such as advanced machining processes, 3D printing, and robotic automation. This not only enhances the precision of the manufacturing process but also ensures that your products are in line with the latest industry standards.

3. Quality Management Systems

Implementing robust quality management systems is imperative for maintaining precision in production. Ensure that your suppliers adhere to internationally recognized quality standards such as ISO 9001 and AS9100 for aerospace applications. Regular audits and inspections should be conducted to verify that these standards are consistently met throughout the production process.

4. Material Selection

The materials used in high-tech manufacturing play a crucial role in achieving precision. Collaborate with suppliers who have expertise in working with advanced materials suitable for your industry. Consider factors such as material hardness, thermal conductivity, and resistance to environmental factors to ensure the longevity and reliability of the final product.

5. Tolerance and Measurement

Precision is often defined by tight tolerances, and high-tech buyers should communicate these specifications clearly with suppliers. Invest in advanced measurement and inspection equipment to verify that the produced components meet the specified tolerances. Regularly calibrate measuring tools to maintain accuracy and reliability in the quality control process.

6. Continuous Improvement

Precision in production is an ongoing pursuit that requires a commitment to continuous improvement. Establish a feedback loop with suppliers to address any deviations or challenges promptly. Encourage open communication and collaboration to identify areas for improvement and implement corrective actions effectively.

7. Risk Mitigation

Identify and mitigate potential risks in the production process to prevent issues that could compromise precision. This includes having contingency plans for supply chain disruptions, implementing redundancy in critical processes, and staying informed about industry trends and regulatory changes that could impact production.

Conclusion

In the dynamic world of high-tech industries, precision in production is non-negotiable. High-tech buyers must take a strategic approach, from selecting the right suppliers to integrating cutting-edge technologies and implementing robust quality control measures. By prioritizing precision, companies can not only meet the stringent requirements of their industries but also gain a competitive edge in delivering reliable and high-quality products.