Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Precision Partnerships: Choosing Your High-Quality SMT AOI Manufacturer

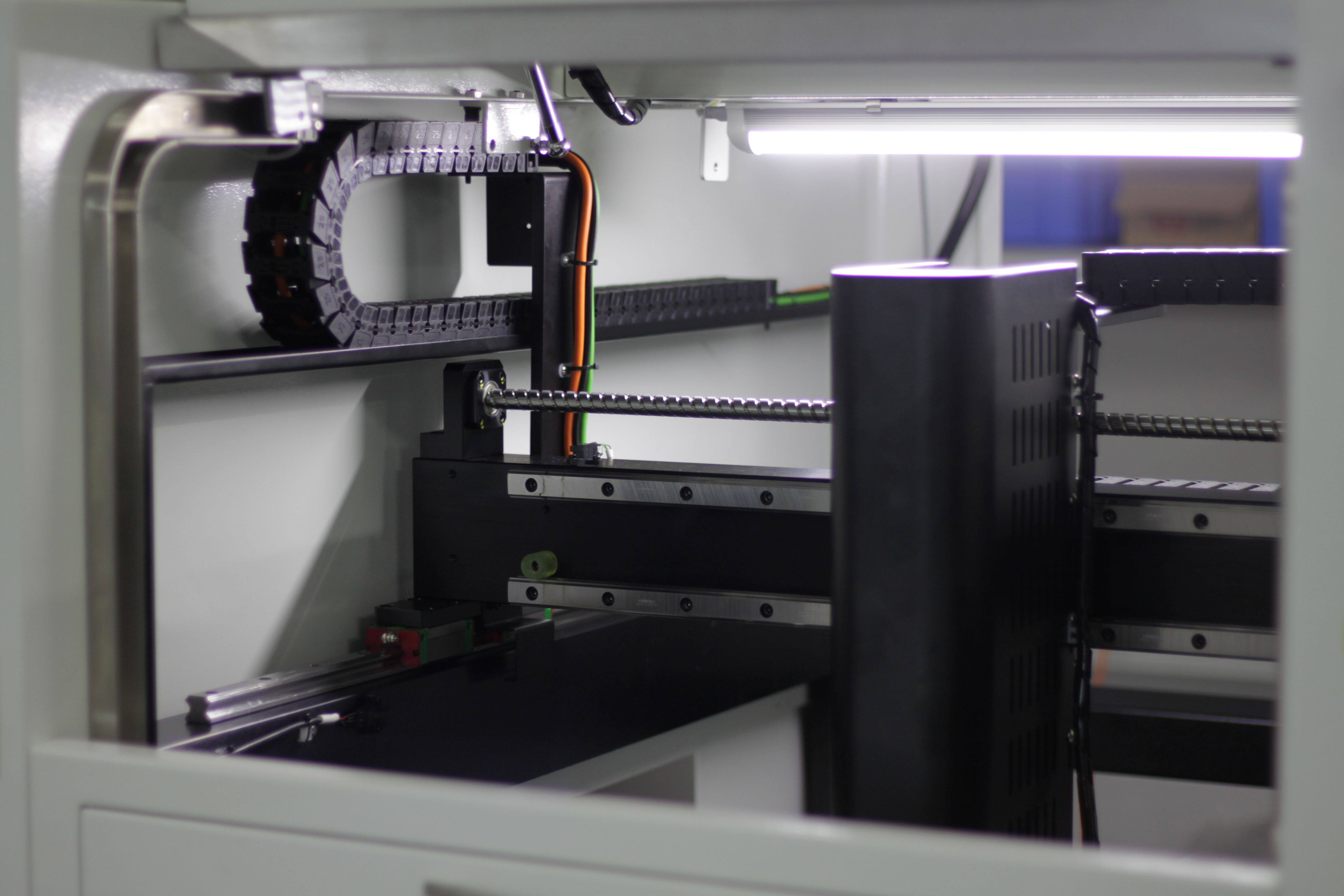

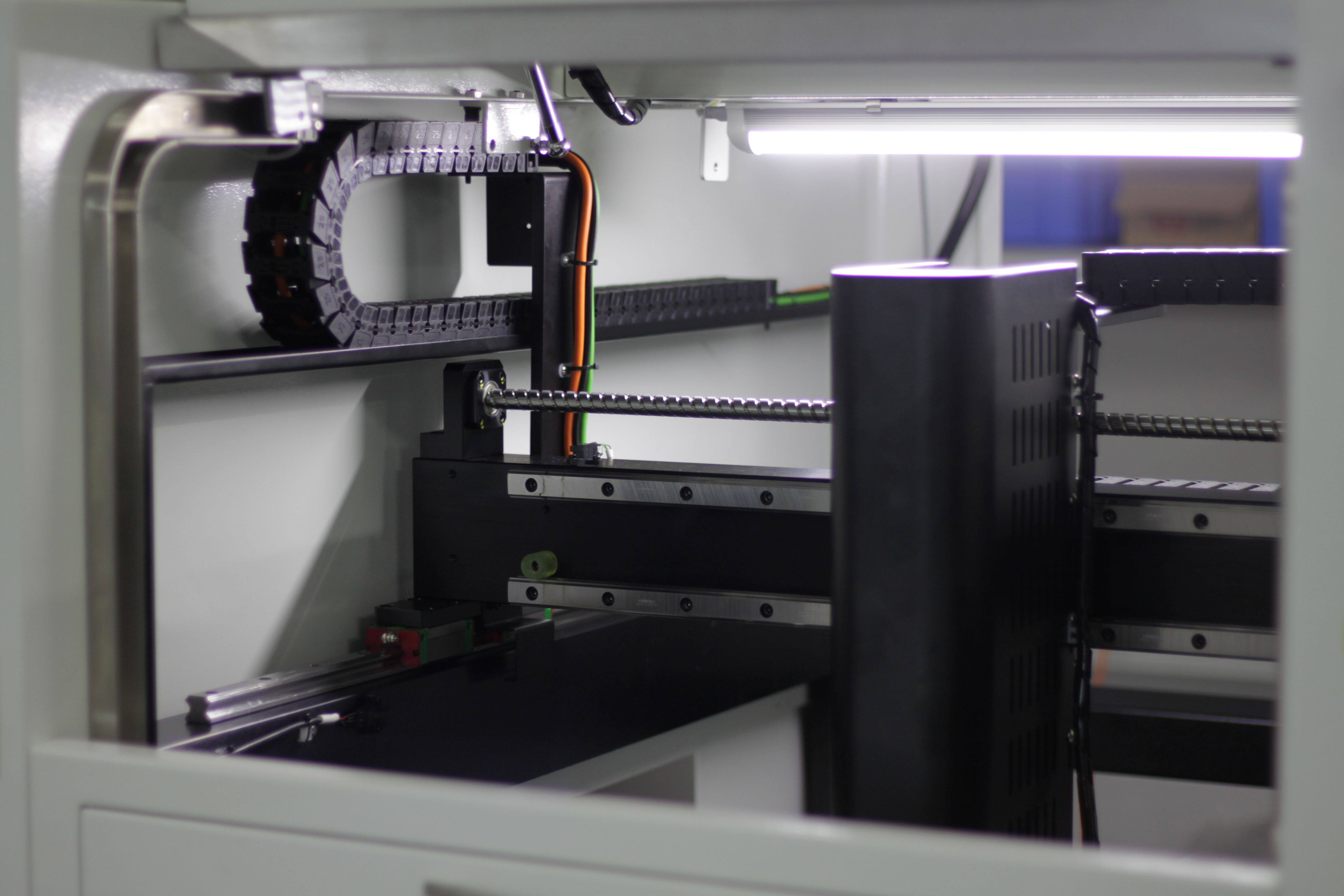

In the intricate world of Surface Mount Technology (SMT), where precision and efficiency reign supreme, the choice of an Automatic Optical Inspection (AOI) machine manufacturer can make or break a production line. Discerning manufacturers understand that partnering with a "high-quality automatic SMT AOI machine manufacturer" is not just a transaction but a strategic investment in the reliability and performance of their operations.

Introduction

The demand for high-quality automatic SMT AOI machines has surged in recent years, mirroring the rapid advancements in electronics manufacturing. As industries embrace the era of Industry 4.0, the need for cutting-edge AOI technology becomes paramount. In this landscape, the right manufacturer acts as a beacon, guiding companies towards seamless integration and unparalleled defect detection.

Key Factors for Consideration

Technology and Features

In the realm of AOI machines, the term "high quality" transcends mere construction. It encapsulates the technological prowess of the equipment. Manufacturers at the forefront of this industry leverage state-of-the-art features like real-time defect analysis, machine learning algorithms, and intuitive user interfaces. Investing in such technology ensures a competitive edge in an ever-evolving market.

Performance Metrics

For manufacturers, performance is non-negotiable. The term "high quality" extends to the consistent and reliable operation of AOI machines. Beyond the glossy brochures, businesses must scrutinise performance metrics. Speed, accuracy, and the ability to adapt to various production scenarios become the benchmarks for a manufacturer's commitment to excellence.

Cost Considerations

Balancing the books is an eternal dance in business, and the acquisition of a high-quality AOI machine is no exception. While upfront costs are crucial, the total cost of ownership takes precedence. Savvy manufacturers weigh the initial investment against long-term benefits, factoring in maintenance, downtime, and the impact on overall production efficiency.

Manufacturer Reputation and Reviews

In the digital age, information flows freely, and reputation precedes any business transaction. Researching and comparing "high-quality automatic SMT AOI machine manufacturers" is a multifaceted process. Delve into customer testimonials, uncovering real-world experiences that traverse industry domains. Case studies offer a panoramic view, revealing the tangible impact of a chosen manufacturer on diverse production landscapes.

Support and Training

A manufacturer's commitment doesn't end with the sale; it extends to post-purchase support and training. Consider manufacturers offering comprehensive technical support, warranty packages, and robust training programmes. The synergy between cutting-edge technology and a knowledgeable workforce propels manufacturing operations towards efficiency and innovation.

Compatibility and Integration

Smooth integration of an AOI machine into existing systems is imperative. A "high-quality automatic SMT AOI machine manufacturer" understands the heterogeneity of production environments. It aligns its products with industry standards, ensuring compatibility and minimizing downtime during installation. Furthermore, the flexibility for future upgrades aligns with the dynamic nature of modern manufacturing.

Regulatory Compliance

In the complex web of manufacturing standards, a high-quality AOI machine is a compliant machine. Manufacturers adhering to industry standards assure a level of quality that aligns with regulatory benchmarks. This not only safeguards the manufacturing process but also positions the business as a reliable player in the industry.

Conclusion

Choosing a "high-quality automatic SMT AOI machine manufacturer" involves a careful dance between technology, cost, and reputation. As industries evolve, so do the demands placed on manufacturers. In this dynamic landscape, a judicious choice not only ensures a smooth production process but also positions a company at the forefront of innovation and reliability. Remember, in the world of SMT, precision begins with the right choice.