Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

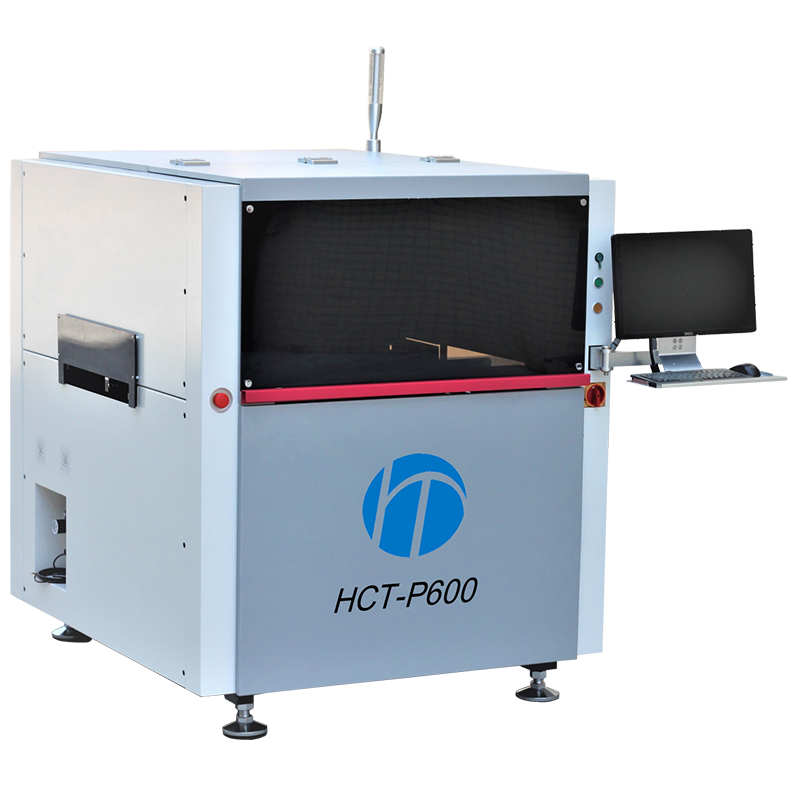

Automatic Solder Paste Printer

Automatic Solder Paste Printer

(2)Surface Mount Technology (SMT) is a critical aspect of modern electronic manufacturing processes, and solder paste printing plays a crucial role in the success of SMT assembly. With the growing demand for smaller and more complex electronic components, there is a need for efficient and precise solder paste printing. This is where the Automatic Solder Paste Printer comes in, offering a reliable and cost-effective solution for printed circuit board (PCB) assembly.

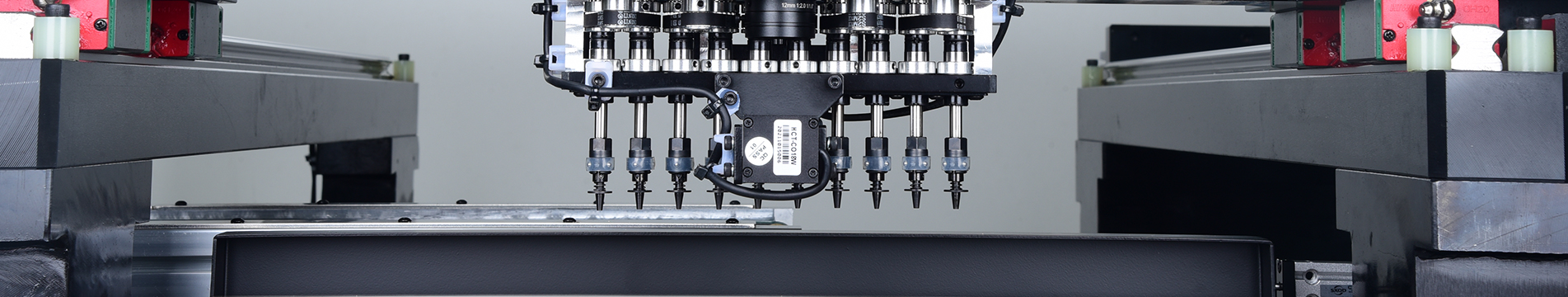

An Automatic Solder Paste Printer is a machine that automates the process of applying solder paste to PCBs. This machine is designed to provide accurate and consistent solder paste deposition, which is essential for producing high-quality PCBs. The Automatic Solder Paste Printer works by using a stencil, which is placed over the PCB, to deposit solder paste on the board. The stencil is usually made of metal or plastic, with cutouts or apertures that correspond to the locations of the components on the board.

The Automatic Solder Paste Printer offers several advantages over traditional manual solder paste printing. First, it reduces the potential for errors caused by human intervention, leading to higher quality and more consistent PCBs. Second, it can handle high volumes of PCBs at a faster rate, which increases productivity and reduces production costs. Third, it minimizes material waste by accurately depositing the right amount of solder paste, reducing the need for rework.

When choosing an Automatic Solder Paste Printer, it is essential to consider factors such as accuracy, speed, and versatility. The printer should be capable of precise alignment and repeatability to ensure accurate and consistent solder paste deposition. It should also have a high throughput, enabling it to handle large volumes of PCBs quickly. Furthermore, the printer should be versatile enough to accommodate different PCB sizes and shapes, with a range of stencil sizes and types.

One popular type of Automatic Solder Paste Printer is the inline model, which is integrated into the production line. This machine is designed to print solder paste on PCBs as they move along the assembly line, eliminating the need for manual handling and reducing the risk of errors. Another type is the batch printer, which is used for low-volume production runs. This machine is designed to print solder paste on a batch of PCBs at once, allowing for more efficient use of time and resources.

In summary, the Automatic Solder Paste Printer is a game-changer in the SMT assembly process. It offers a reliable, cost-effective, and efficient solution for PCB production, ensuring accurate and consistent solder paste deposition. With the right machine, businesses can significantly improve their production processes, increase efficiency, and reduce costs. Choosing an Automatic Solder Paste Printer that meets the specific needs of the business is crucial for achieving the desired results.

HCT offers a variety of automatic SMT Solder Paste Printers, including options with automatic alignments, such as fully automatic inline printers and automatic options that have vision assist. The HCT Automatic Solder Paste Stencil Printer is cost-efficient and has precise alignment for the stencil.

We are a global supplier of precision Solder Paste Stencil Printer. Provide the perfect way to complete your assembly line.

High Accuracy Automatic Solder Paste Stencil Printer

The system offers three different cleaning techniques—dry cleaning, wet cleaning, and vacuum—that can be combined in any way and support manual cleaning in the production interface, cutting down on cleaning time and boosting production effectiveness.

Economical Full Automatic Stencil Printing Machine

The scraper beam of the gantry type can float the scraper head, and the scraper rises and falls automatically. All semi-automatic printing presses can employ stencils with the stencil bracket. the one-stage conveying system, the motor-driven precision ball screw automatic clamping device, and the PCB board automatic positioning.