Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Loader & Unloader

Loader & Unloader

(4)PCB Loader & PCB unloader from a professional China factory & supplier. Start and finish conveyors for PCB assembly line.

Load and unload PCBs from your assembly line is the first and the last conveyor in the SMT production line.

HCT offers PCB loaders and PCB unloaders. If you don't find e.g. the PCB board loader you are looking for below, please contact us.

We're well-known as one of the leading auto loader&unloader machine manufacturers and suppliers in China. Our factory offers high-quality auto loader & unloader machines made in China at competitive prices. Welcome to place an order.

SMT Automatic PCB Unloader machine

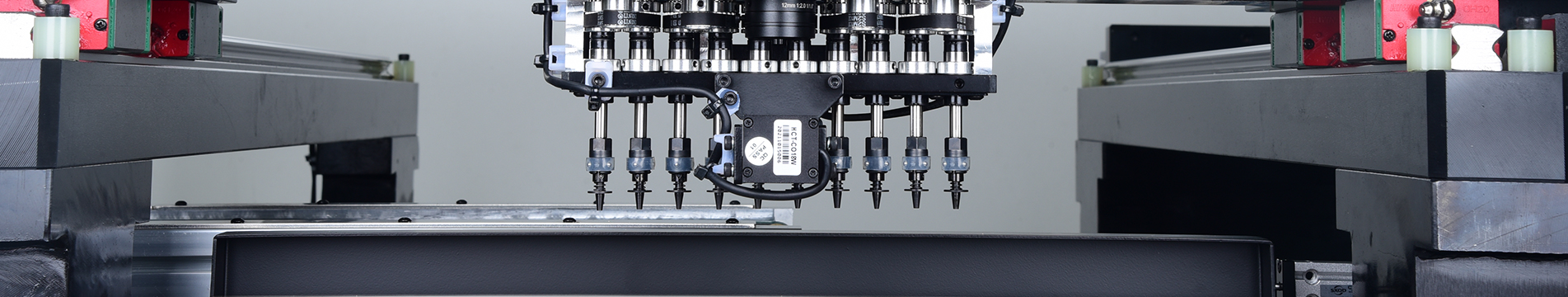

The casting lifting table structure of the PCB unloader machine is stable, which increases the equipment's stability. The production line runs smoothly thanks to the control system's independent intellectual property rights, multifunctional electrical circuits and programming, and consistent performance. Other automation equipment can communicate using a standard SMEMA communication interface. The SMT assembly line depends heavily on the SMT loader machine.

SMT Automatic PCB Loader Machine

Repair and maintenance procedures for the loader machine's gearbox include draining the oil, cleaning the interior with diesel or gasoline, and replacing the oil with new smooth oil after it has been drained. Add right away in the centre of the viewing area. In the future, changing the lubricating oil once a year is sufficient. The gearbox could become overheated from using too much lubricant, and an overloaded motor could activate the motor maintenance switch.

Automatic Wave Soldering Unloader - China SMT Line Unloader Equipment

This conveyor is used to remove PCBs or pallets from an adjustable-angle wave soldering equipment. The downstream machine is shown a PCB or pallet at eye level by the decline part.

DIP Wave Solder Infeed Conveyor - China Automatic SMT Infeed Conveyor

To accomplish the goal of welding, wave soldering involves bringing the plug-in board's welding surface into direct contact with the hot liquid tin. The primary component is solder bar.