Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

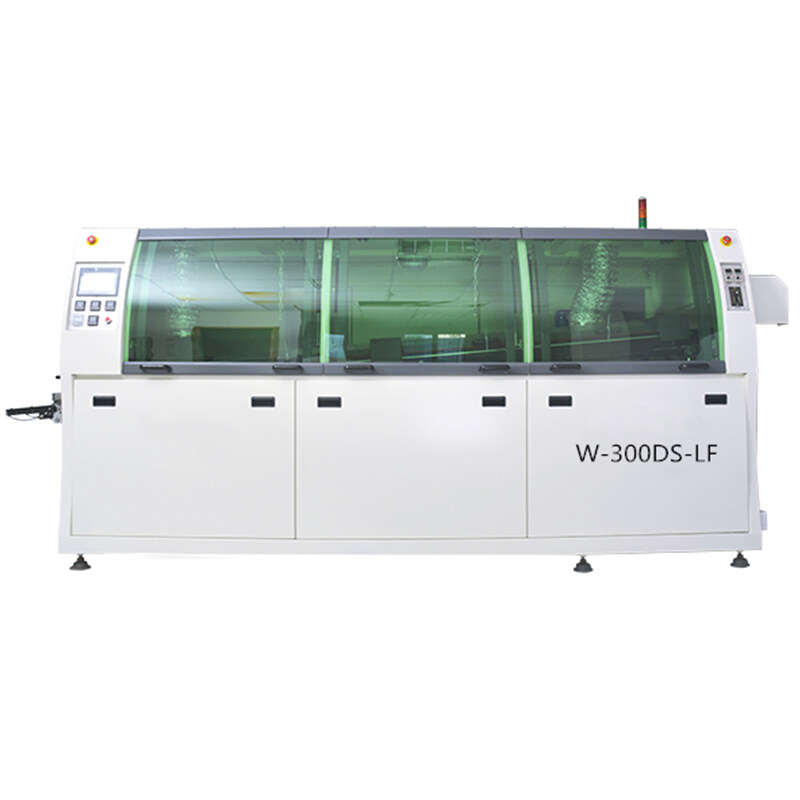

Economic Lead-free Double-Wave Soldering Machine

Effective, energy-saving, environmentally friendly, lead-free, safe, and brand-new design, with easy operation and convenient maintenance. Automatic board input, automatic power system, and automatic frequency converter control. Flux spray system with accurate and dependable PLC control, scanning spray nozzle, Japanese nozzles, and rodless pneumatic cylinders.

Small Lead-Free Double-Wave Soldering Oven

Flux spray system with accurate and dependable PLC control, scanning spray nozzle, Japanese nozzles, and rodless pneumatic cylinders. With non-level frequency conversing speed adjustment and auto-synchronous board feeding features, the conveying power system is automatic. The preheating system uses remote infrared ceramic heating pipes, which guarantees a good heat preservation effect, a quick heating up time, and an even temperature.

1.2M Semi-automatic Solder Paste Printer

To direct the solder paste into the required locations, a stencil is employed. The stencil was used because the product shouldn't cover the full surface. Your "how to apply solder paste" issues are all resolved by the solder paste stencil. The paste is fed into the pick and place machine after being applied on the printed circuit board. This includes the elements that it holds in place.

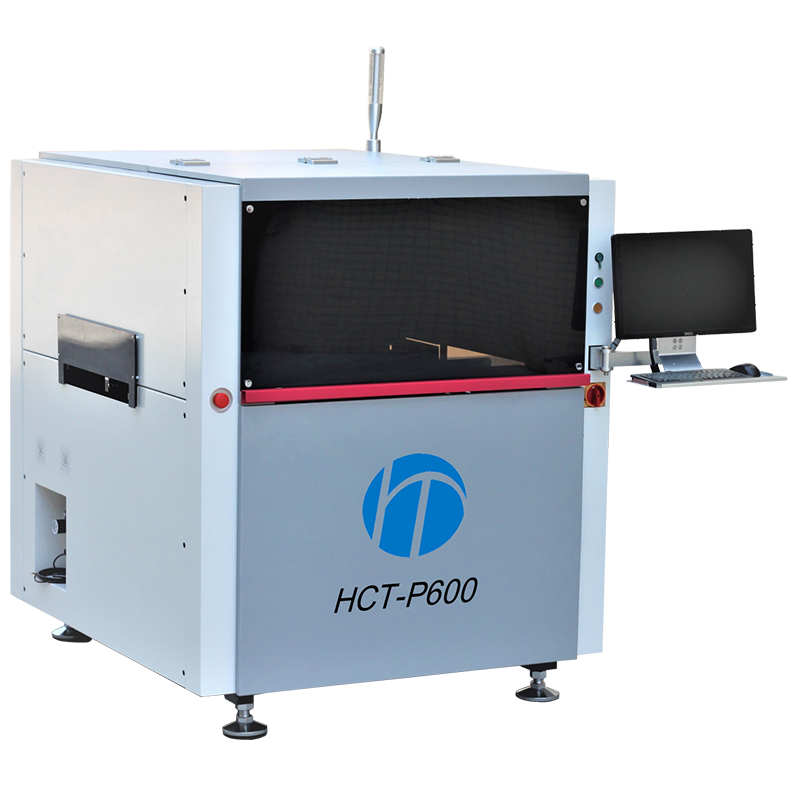

High Accuracy Automatic Solder Paste Stencil Printer

The system offers three different cleaning techniques—dry cleaning, wet cleaning, and vacuum—that can be combined in any way and support manual cleaning in the production interface, cutting down on cleaning time and boosting production effectiveness.

Economical Full Automatic Stencil Printing Machine

The scraper beam of the gantry type can float the scraper head, and the scraper rises and falls automatically. All semi-automatic printing presses can employ stencils with the stencil bracket. the one-stage conveying system, the motor-driven precision ball screw automatic clamping device, and the PCB board automatic positioning.

SMT General Buffer Conveyor SMT Single / Dual Rail Conveyor

SMT Peripheral Equipment, Mass Soldering, Small Dip Soldering Machine, Pick & Place Machine, We take great pride in a great reputation among our customers for our exceptional product or service excellent, competitive rate, and also the best services. Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We warmly invite clients from all around the world to build long-lasting business relationships that benefit both parties and look forward to a bright future together.

DIP Wave Solder Infeed Conveyor - China Automatic SMT Infeed Conveyor

To accomplish the goal of welding, wave soldering involves bringing the plug-in board's welding surface into direct contact with the hot liquid tin. The primary component is solder bar.

Automatic Wave Soldering Unloader - China SMT Line Unloader Equipment

This conveyor is used to remove PCBs or pallets from an adjustable-angle wave soldering equipment. The downstream machine is shown a PCB or pallet at eye level by the decline part.

SMT Automatic PCB Loader Machine

Repair and maintenance procedures for the loader machine's gearbox include draining the oil, cleaning the interior with diesel or gasoline, and replacing the oil with new smooth oil after it has been drained. Add right away in the centre of the viewing area. In the future, changing the lubricating oil once a year is sufficient. The gearbox could become overheated from using too much lubricant, and an overloaded motor could activate the motor maintenance switch.

SMT Automatic PCB Unloader machine

The casting lifting table structure of the PCB unloader machine is stable, which increases the equipment's stability. The production line runs smoothly thanks to the control system's independent intellectual property rights, multifunctional electrical circuits and programming, and consistent performance. Other automation equipment can communicate using a standard SMEMA communication interface. The SMT assembly line depends heavily on the SMT loader machine.