Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Economic Lead-free Double-Wave Soldering Machine

Effective, energy-saving, environmentally friendly, lead-free, safe, and brand-new design, with easy operation and convenient maintenance. Automatic board input, automatic power system, and automatic frequency converter control. Flux spray system with accurate and dependable PLC control, scanning spray nozzle, Japanese nozzles, and rodless pneumatic cylinders.

Lead-free Double-Wave Soldering Machine

A lead-free double-wave soldering machine is a specialized equipment used in electronics manufacturing for the soldering of printed circuit boards (PCBs) using lead-free solder. Here's some information about a lead-free double-wave soldering machine:

Function and Purpose:

- Soldering process: The primary function of a lead-free double-wave soldering machine is to apply molten solder onto PCBs to create reliable electrical connections between components and the PCB.

- Lead-free soldering: These machines are specifically designed to work with lead-free solder alloys, which comply with environmental regulations and eliminate the use of toxic lead-based solders.

- Double-wave soldering: The machine utilizes two separate solder waves, typically called the preheating wave and the main wave, to ensure thorough solder coverage and proper solder wetting on the PCB.

Features of a Lead-free Double-Wave Soldering Machine:

- Preheating zone: The machine includes a preheating zone to raise the temperature of the PCB and components before they come into contact with the solder waves. This helps to activate fluxes, remove moisture, and ensure proper solderability.

- Dual solder wave system: The machine features two separate solder waves, with the preheating wave providing initial wetting and activation of flux, followed by the main wave for complete soldering and formation of strong solder joints.

- Adjustable parameters: Parameters such as wave height, wave temperature, conveyor speed, and solder dwell time can be adjusted to meet specific soldering requirements and accommodate different PCB designs.

- Fluxing system: A fluxing system is integrated into the machine to apply flux onto the PCB before solder application. Flux helps to remove oxides and improve solder wetting and adhesion.

- Conveyor system: The machine is equipped with a conveyor system that transports the PCB through the soldering process, ensuring consistent and controlled contact with the solder waves.

Advantages of using a Lead-free Double-Wave Soldering Machine:

- Compliance with regulations: Using lead-free solder eliminates the use of hazardous lead-based solders and ensures compliance with environmental regulations.

- Enhanced reliability: The double-wave soldering process provides thorough solder coverage, good wetting, and strong solder joints, enhancing the long-term reliability of PCBs.

- Versatility: A lead-free double-wave soldering machine can handle a wide range of PCB sizes, component types, and assembly configurations, making it suitable for various applications.

- Process control: Adjustable parameters and precise control systems allow for fine-tuning and optimization of the soldering process, ensuring consistent and reliable results.

Considerations when using a Lead-free Double-Wave Soldering Machine:

- Temperature management: Proper temperature control is crucial to ensure optimal soldering results and prevent issues such as cold solder joints or overheating of sensitive components.

- Flux selection: Choosing appropriate lead-free fluxes that are compatible with the solder alloy and PCB materials is essential for achieving good solder wetting and minimizing defects.

- Maintenance and cleaning: Regular maintenance, cleaning, and replacement of solder nozzles, wave guides, and filters are necessary to maintain optimal performance and minimize solder contamination.

lead-free double-wave soldering machine offers advantages in terms of compliance, reliability, and process control. By providing a precise and efficient soldering process, these machines contribute to high-quality PCB assembly while meeting environmental requirements.

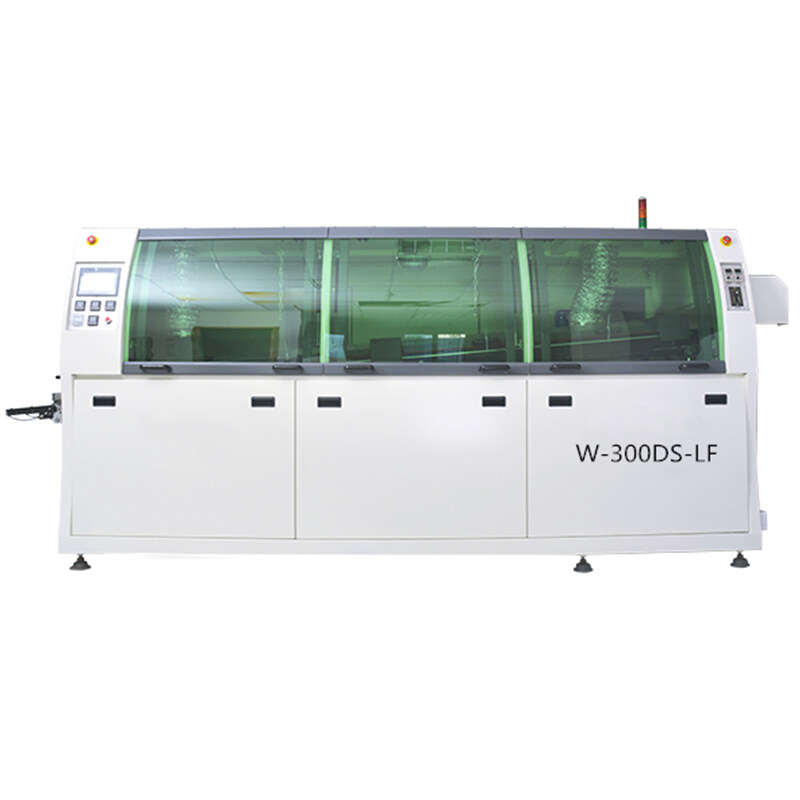

TECHNICAL PARAMETER - Lead-free Double-Wave Soldering Machine

|

Model No. |

W-300DS-LF |

|

Transportation System |

|

|

PCB Width |

Max.320mm |

|

PCBConveyorHeight |

750±20mm |

|

PCBConveyorSpeed |

0-1.8m/min |

|

PCBConveyorDirection |

L→R(R→L option) |

|

Spraying System |

|

|

Spraying Way |

Stepper Motor & ST-6 nozzle |

|

Flux storage tank |

Max.5.2L |

|

Preheating System |

|

|

PreheatingLength |

1800mm |

|

PreheatingZone |

3 zones of hot air, independent control |

|

Preheating Temperatures |

Max. 220℃ |

|

Preheating Power |

6KW |

|

Soldering System |

|

|

ApplicableSolderType |

Lead-free |

|

Melting Tin Quantity |

300KG |

|

WaveSolderingFurnacePower |

12KW |

|

General Parameters |

|

|

Power Supply |

3 Phase 380V(220V option) |

|

AirSupply |

4-7kg/cm2 12.5L/min |

|

Start Power |

18KW |

|

Working Power |

MAX5-6KW |

|

TemperatureControl |

RCKTemperatureControlModule |

|

Control Mode |

XINJE PLC + Touch Screen |

|

Weight |

Max800kg |

|

Body Dimensions |

L3200xW1200xH1600 MM |

|

Total Dimensions |

L3200xW1200xH1600 MM |

PRODUCT SPECIFICATION - Lead-free Double-Wave Soldering Machine

China SMD Pcb Wave Soldering Machine

A China SMD PCB wave soldering machine is a specialized equipment manufactured in China that is used for soldering surface mount device (SMD) components onto printed circuit boards (PCBs) using the wave soldering process. Here's some information about a China SMD PCB wave soldering machine:

Function and Purpose:

- Soldering of SMD components: The primary function of a China SMD PCB wave soldering machine is to solder SMD components onto PCBs using the wave soldering technique.

- Wave soldering process: These machines utilize a molten solder wave to create reliable electrical connections between SMD components and the PCB, ensuring proper solder wetting and strong solder joints.

Features of a China SMD PCB Wave Soldering Machine:

- Conveyor system: The machine is equipped with a conveyor system that transports PCBs through the wave soldering process, ensuring consistent and controlled contact with the solder wave.

- Preheating zone: A preheating zone is integrated into the machine to raise the temperature of the PCB and components before they come into contact with the solder wave. This helps to activate fluxes, remove moisture, and ensure proper solderability.

- Adjustable parameters: Various parameters such as wave height, wave temperature, conveyor speed, and solder dwell time can be adjusted to meet specific soldering requirements and accommodate different PCB designs and component sizes.

- Fluxing system: A fluxing system is typically included in the machine to apply flux onto the PCB before solder application. Flux helps to remove oxides and improve solder wetting and adhesion.

- Temperature control: The machine has temperature control mechanisms to maintain the proper solder wave temperature and prevent issues such as cold solder joints or overheating of sensitive components.

Advantages of a China SMD PCB Wave Soldering Machine:

- Cost-effective: China is known for manufacturing competitive and cost-effective equipment, making China SMD PCB wave soldering machines an attractive option for businesses.

- Versatility: These machines can handle a wide range of SMD component sizes and PCB configurations, making them suitable for various applications.

- Efficient soldering process: The wave soldering process offers fast and efficient soldering of SMD components, ensuring reliable electrical connections with good solder wetting and strong solder joints.

- Process control: Adjustable parameters and temperature control systems allow for fine-tuning and optimization of the soldering process, ensuring consistent and reliable results.

Considerations when using a China SMD PCB Wave Soldering Machine:

- Quality and reputation: When considering a China-made machine, it is important to research and select reputable manufacturers known for producing high-quality equipment.

- Technical support and after-sales service: Ensure that the manufacturer provides reliable technical support and after-sales service to address any issues or concerns that may arise during the installation or operation of the machine.

- Compliance and certifications: Ensure that the machine meets international quality and safety standards, such as CE certification, to ensure its reliability and safety.

China SMD PCB wave soldering machine offers advantages in terms of cost-effectiveness, versatility, and efficiency. By utilizing the wave soldering process, these machines contribute to high-quality PCB assembly and reliable electrical connections between SMD components and PCBs.

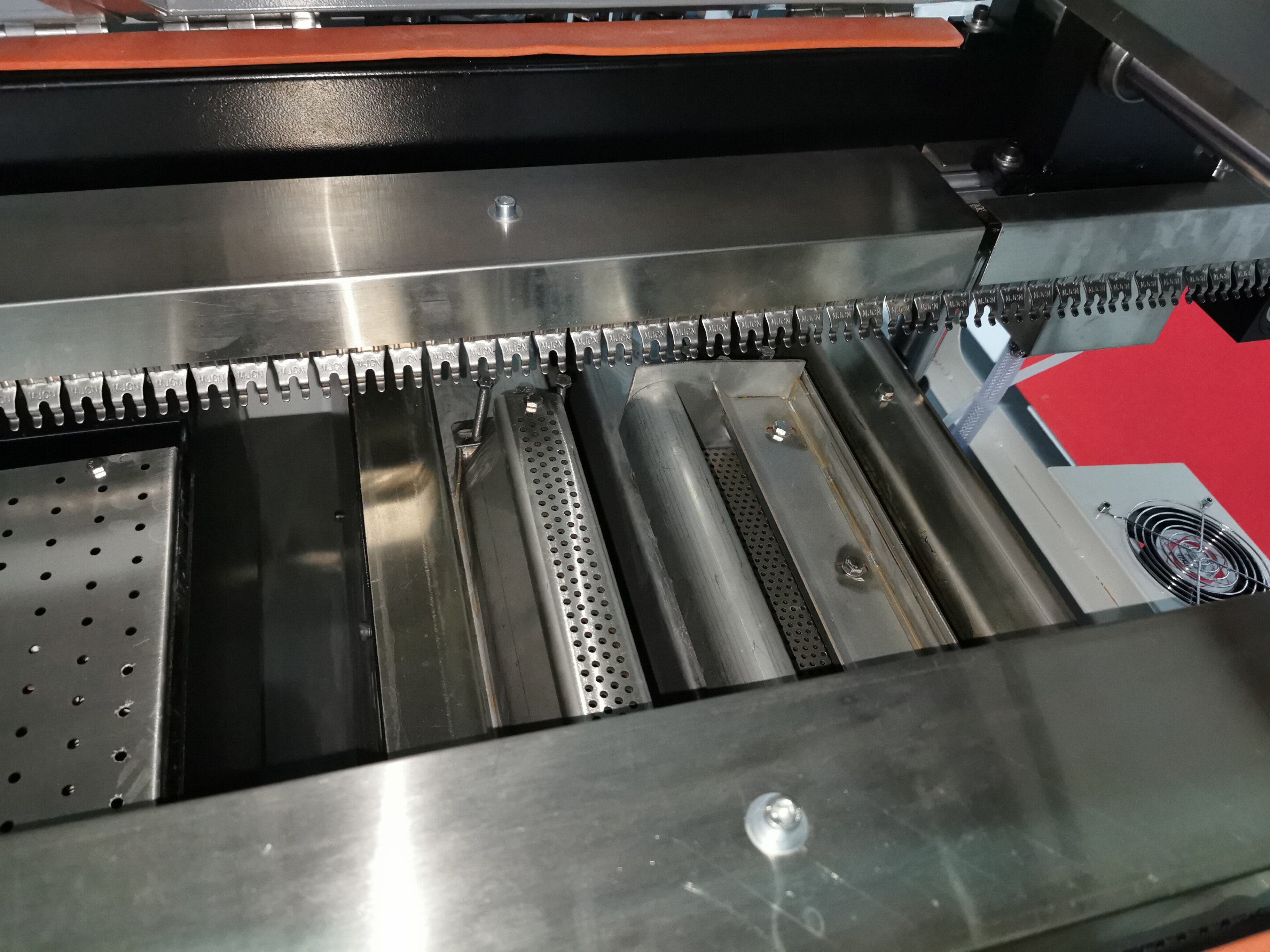

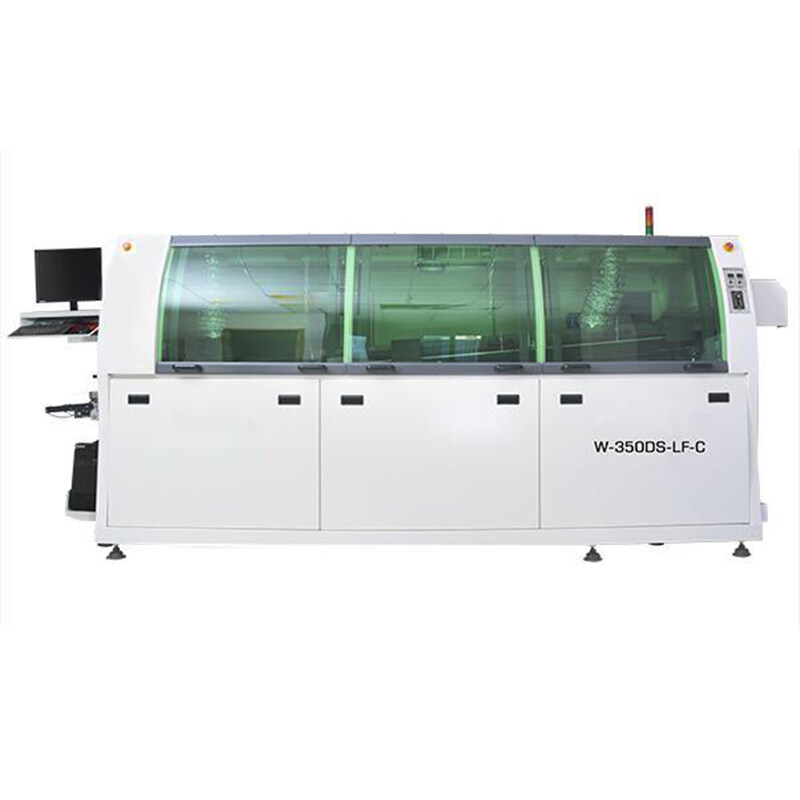

PRODUCT DISPLAY - Lead-free Double-Wave Soldering Machine